New ReleasesPage 5

arrange in order

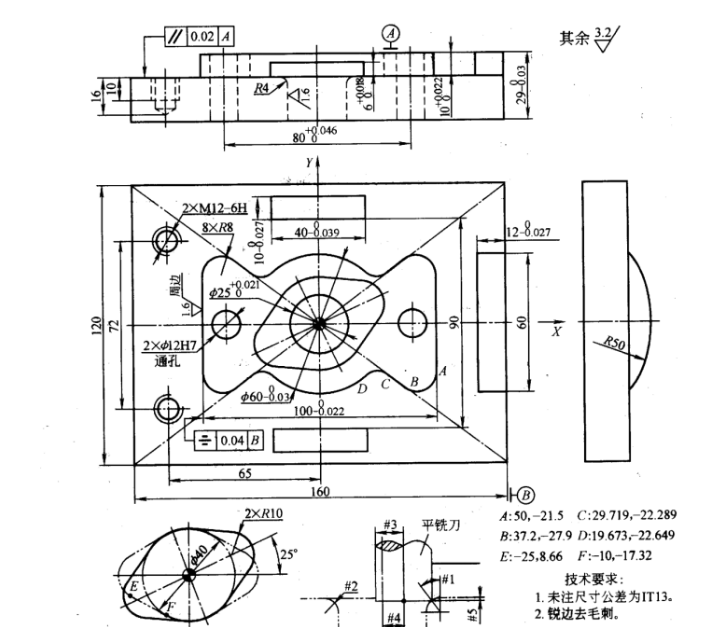

Aluminium and Stainless Steel – Properties and Challenges of Different Metals in Precision Machining

How Material Selection Determines the Success of Machining In precision machining, material selection is not merely a cost consideration but a core factor determining component performance, machining efficiency, and final quality. Aluminium alloys and stainless steels are the most...

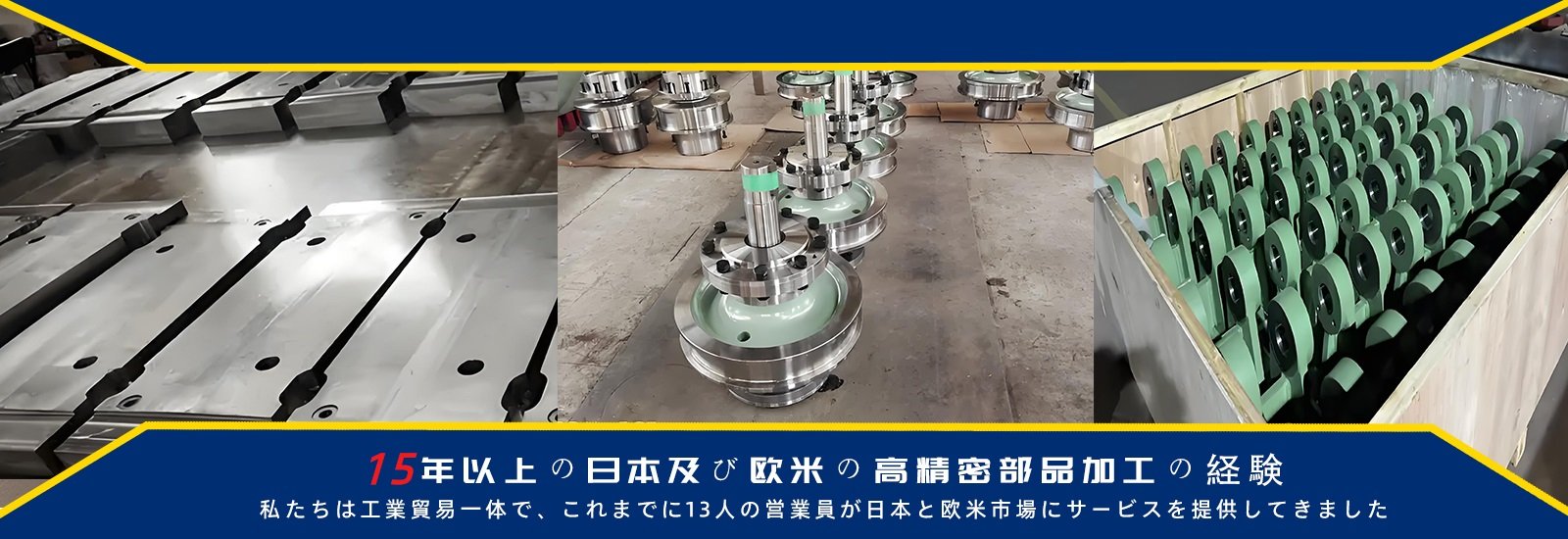

Large-scale Gantry CNC machining, industrial robot spare parts, steel plates, and production support technologies

Large-scale Gantry CNC Machining, Industrial Robot Spare Parts, Steel Plates, and Production Supporting Technologies Industrial Robot Parts are actually made in the field of ...

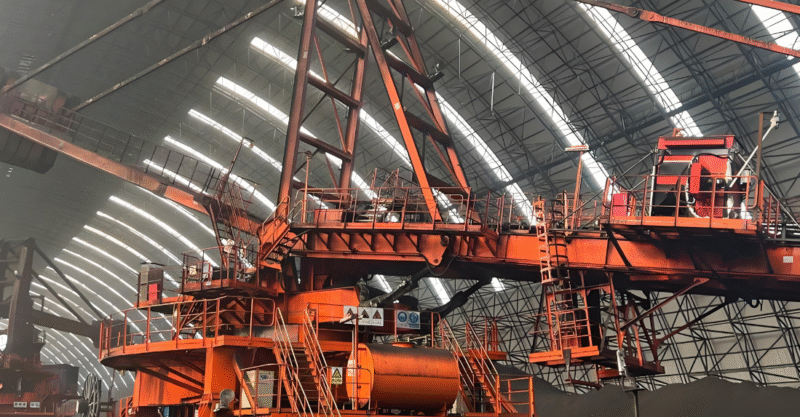

Thorough Repair of Rotary Bearing: Early Warning から Repair Completed まで126 Days ("スタッカーリクレーマー Rotary Bearing Troubleshooting and Repair Programme")

The port of Liaoning Province is the first place where the No.8 Sta... The device has been in use for 11 years...

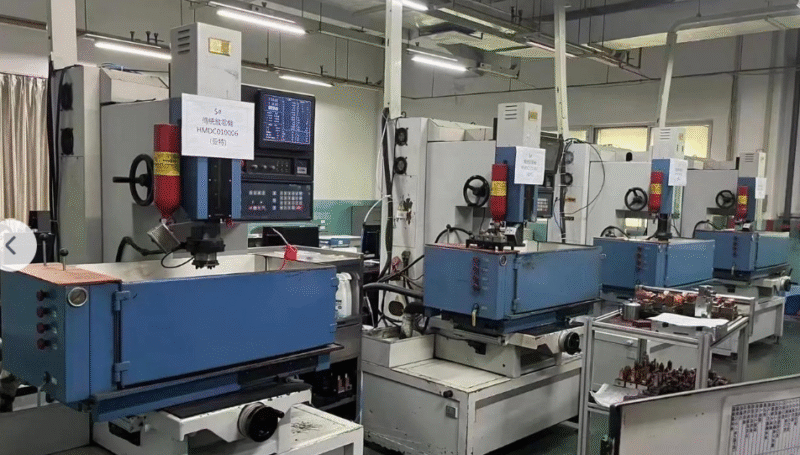

Processing Machines and Equipment: Defining Nuclear Power in Modern Manufacturing

Behaviour of Machining Machines and Equipment for Rotary Disc Machining, Flatbed Machining, Grinding Machining and CNC Machining. Help: How can I keep track of my machining equipment? This page contains information on rotary discs, flute discs, grinding discs, CNC ...

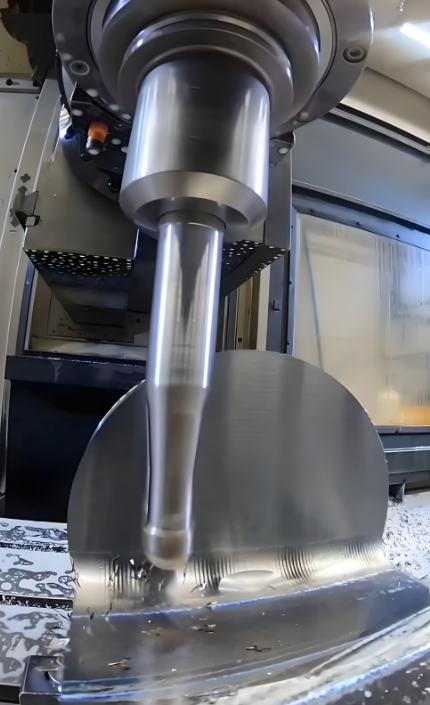

CNC Masking and Revolving: The Driving Force for High-Precision Development in Modern Manufacturing Industry

Mechanical Processing by Numerical Valve Machining: The Advancement of High Precision in Modern Manufacturing Industry The world's manufacturing industry is attempting to achieve a high degree of efficiency and precision through numerical value machining, and the high degree of ...

Cutting and Flatbed Machining: Concrete Technology and Innovative Aplications for Modern Manufacturing (Analysis of Flatbed Machining and Grinding: Integration of Efficiency and Precision Innovation)

Machining Flatbed and Grinding: Concrete Technology and Innovative Applied Technology in Modern Manufacturing Industry Automobile Engine and Aerospace Precision Components, Medical Equipment and Intermediate and Core Components, Cutting Flatbed and...

The Whole Process of Integration of Older Structural Rehabilitation: A Practical Analysis of Technology Selection and Investment Return ("Analysis of Integration of Structural Rehabilitation Technologies and Investment Return")

In China, the average life expectancy of the port has exceeded 15 years, and the average life expectancy of the 12-base unit has been replaced by a new unit, as described in the following section. Stark and Recreational Intelligence has been implemented, and the community has been able to...

The Basics of Machining: Traditional Work and Modern Applications

Explore the world at the heart of machining. This article details the principles, characteristics and applicable scenarios of traditional machining processes such as turning, milling, drilling and grinding to help you choose the most appropriate machining method for your project. Machining, as the cornerstone of manufacturing, refers to the use of cutting tools through mechanical force from...

Rotary disc machining, flues machining, drilling machining, and general machining engineering for mechanical machining are explained.

The world of machining Rotary disc machining and Flatbed machining is a world of snazzy "weapons" that make it possible to shape materials with precision. Rotary disc machining, Flatbed machining, Drill machining, Grinding machining, and others are available outside of the specialist...

Coatings Technology Details: Comparison of Stainless Steel and Carbon Steel Rebent and Welding Processing Techniques and Application to Industry

Preface: Location of the problem - Stainless steel and carbon steel are the most commonly used metallic materials. What is the difference between the two in terms of the resistance of Rebettes to dissolution? What is the result in the case of an indirect selection? Material Characteristics: Ste...

.jpg)