arrange in order

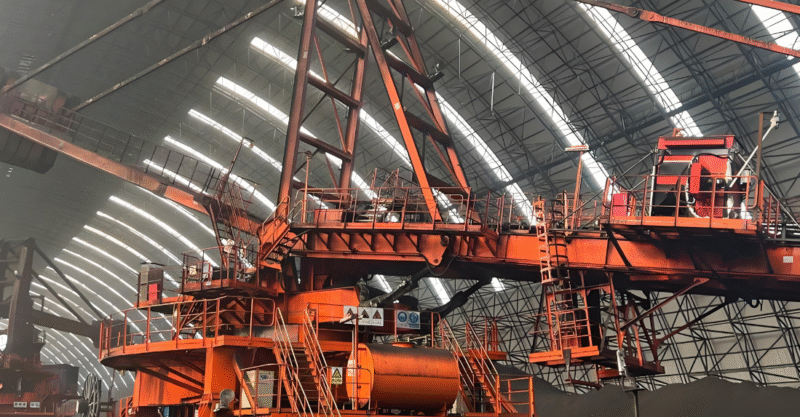

Thorough Repair of Rotary Bearing: Early Warning から Repair Completed まで126 Days ("スタッカーリクレーマー Rotary Bearing Troubleshooting and Repair Programme")

The port of Liaoning Province is the first place where the No.8 Sta... The device has been in use for 11 years...

What is the scope of Rebelt Welding? A General Analysis of the Types of Operations and Works Involved

What is the scope of Rebetti's work? Types of Works and Prospectus 両面から総合的に分析 Meta Description: "リベッティングはどのカテゴリーに属するか "について混乱していますか? This entry is about the types of operations ...

The Whole Process of Integration of Older Structural Rehabilitation: A Practical Analysis of Technology Selection and Investment Return ("Analysis of Integration of Structural Rehabilitation Technologies and Investment Return")

In China, the average life expectancy of the port has exceeded 15 years, and the average life expectancy of the 12-base unit has been replaced by a new unit, as described in the following section. Stark and Recreational Intelligence has been implemented, and the community has been able to...

Coatings Technology Details: Comparison of Stainless Steel and Carbon Steel Rebent and Welding Processing Techniques and Application to Industry

Preface: Location of the problem - Stainless steel and carbon steel are the most commonly used metallic materials. What is the difference between the two in terms of the resistance of Rebettes to dissolution? What is the result in the case of an indirect selection? Material Characteristics: Ste...

お近くのサービスをお探しですか?2026 リベット溶接業業者ランキング・選択ガイド

Rebelt Soldering Plant, Rebelt Soldering in the Community, Selection of Rebelt Soldering Plants, Outline of Regional Ranking Journalists Hajime : Conceptual efficiency, logistic concepts, and quality control points of view, and selection of a local expert m...

Rebettienging: Rebettienging technology is the first technology used in the modern manufacturing industry to provide a reliable and highly reliable joint with a strong undercut.

Rebate Soldering Bonding Engineering in Modern Manufacturing Industry A strong and reliable bonding with high reliability has been started by rebate and solvent joining technology. In today's manufacturing industry, the choice of joining technology can have a direct impact on the quality and performance of products. Re...

Rehabilitation of dissolution: What is the best way to avoid dissolution failures due to the "dissolution" problem?

Analysis of the Half-Field Payment Deficiency: How to Avoid Failure to Solve "Dissolving" Problems? Failure of the joining process can be a problem with materials, and there are many minor problems with the "dissolution" process. Understanding Dissolution...

Soldering and Sheet Metal Assembly - Full Programmes of Rebending and Soldering Processes

Rebate Welding Process, Welding Sheet Metal Assembly Wins Tope Full Engineering Services Summary of Journalists Hajime: The modern manufacturing industry is a necessity for the integration of the services. The complete flow of parts from the drawing to the finished product is clear...

The Future of Rebelt Soldering Processing Workshop: Automation and Intelligentisation (Automation and Intelligentisation is a problem of choice, Rebelt Soldering Processing Workshop's Existence and Development).

Future of the Rebelt Welding Workshop: Automation and Intelligent Transformation 1 Changes and Opportunities in the Industry The basic services and opportunities in the manufacturing industry, Rebelt Welding and Welding Processing are experiencing significant technological changes. Traditional Welding and Rebate...

How to Select a Reliable Aluminium Alloy Rivet Welding Service Provider? Six Evaluation Criteria

The Importance of Selecting an Aluminium Alloy Rivet Welding Service Provider Aluminium alloys are widely utilised in sectors such as aerospace, automotive manufacturing, and shipbuilding due to their characteristics including light weight, corrosion resistance, and high strength.