arrange in order

What is the scope of Rebelt Welding? A General Analysis of the Types of Operations and Works Involved

What is the scope of Rebetti's work? Types of Works and Prospectus 両面から総合的に分析 Meta Description: "リベッティングはどのカテゴリーに属するか "について混乱していますか? This entry is about the types of operations ...

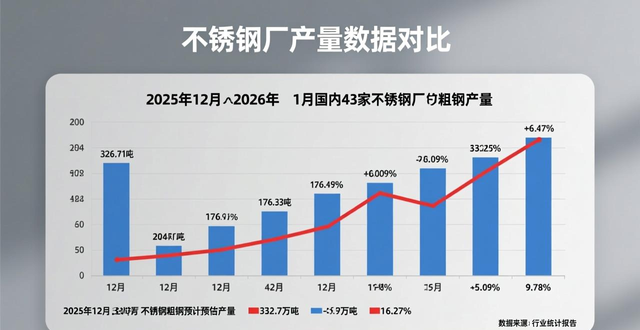

Stainless steel: A raw material solution that maintains a strong impact counter and competitive edge.

Mysteel reports that the price of Wuxi Hongwang 304 cold rolled-up steel is now RMB13,900/tonne on 12 January, up from RMB100/tonne on 1 January. Foshan Hongwang 304 cold intermediate pressure welding price is RMB13,800 per tonne.

耐放射線性と耐腐食性を備えています。原子炉の「ステンレス鋼ライニング」はどれほどすごいのでしょうか? | 「科学はここにある・専門家が対面」溶接品質シリーズ(27)

シリンダーアセンブリの構造は、主にフランジパイプセクション、シリンダー本体、下部ヘッド、出口パイプを含む従来の圧力容器といくつかの類似点があります。シリンダの大きさについては、図2...

Welding Prospectus and Dissolution Technology: A Revolution in Joining and Pantallising for Modern Manufacturing" (A detailed introduction to the latest advances in Welding Prospectus and Dissolution Technology)

Solvent Joining Engineering and Dissolution Technology: A Revolution in Modern Manufacturing by Continuous Joining and Pantallising The ミクロな連結からマクロな成型にまるまにまなまなにまななまななまにまななまにまななまにまななまななまだすす。

The Whole Process of Integration of Older Structural Rehabilitation: A Practical Analysis of Technology Selection and Investment Return ("Analysis of Integration of Structural Rehabilitation Technologies and Investment Return")

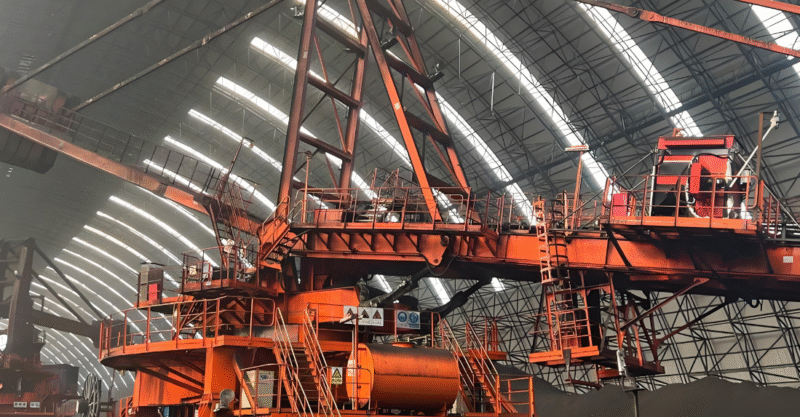

In China, the average life expectancy of the port has exceeded 15 years, and the average life expectancy of the 12-base unit has been replaced by a new unit, as described in the following section. Stark and Recreational Intelligence has been implemented, and the community has been able to...

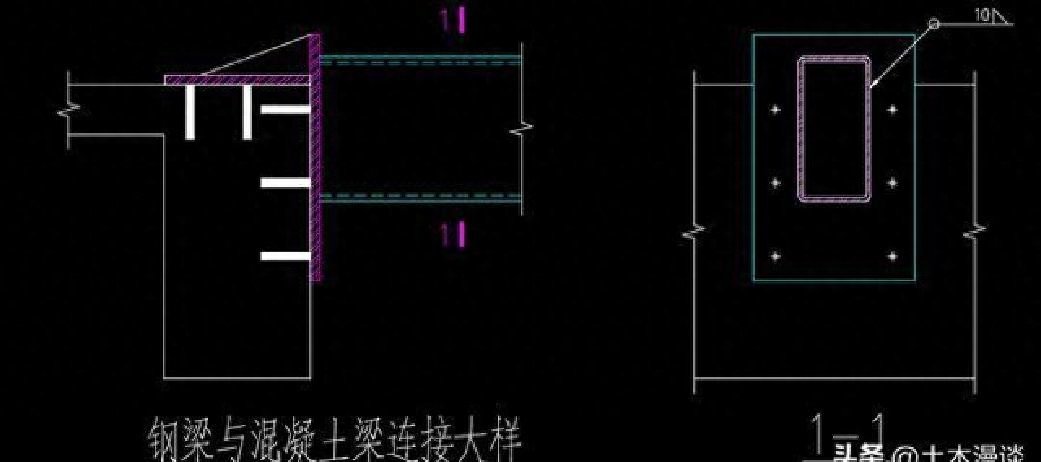

鉄骨梁の終点ノードはヒンジで固定されるように設計されていますが、図面では固定されています。

現場での作業は修正のため中止されました。計算中、梁の端はヒンジ付きジョイントとして扱われましたが、ビームの円全体が現場で溶接されました。これは、ヒンジ付き接続を剛接続に変えるのと同...

Rebett Solventing Solventing and Dissolving Technology: A Perspective on Modern Manufacturing Industry

Rebate Joining: A Modern Approach to Manufacturing In the everlasting process of joining metals, there is a fine connection between materials science and fluid mechanics. In the field of joining technology in manufacturing industry, the topic of "Rebate joining" has been...

Enhancing Production Efficiency and Consistency through Automated Robot Rivet Welding

Amidst the wave of automation, the rivet welding revolution As global manufacturing transitions towards Industry 4.0 and China's "Made in China 2025" initiative, rivet welding processes—historically reliant on human skill—are now undergoing a transformative shift driven by automation...

韓国ヒュンダイ SM-316L ステンレス鋼溶接ワイヤ

お問い合わせ歓迎: 155-5004-8123SM-316L ステンレス鋼溶接ワイヤ、溶接ニーズ向けに特別に設計されています。高品質な材質を使用しており、しっかりとした安定した溶接が可能です。さまざまな...

Rebent Welding Process: Industry-orientated high-precision metal joining technology

Rebate welding process is a technology that combines mechanical bonding (rebate) and fusion bonding (fusion bonding) to achieve strong and durable bonding of metals and plastics and other dissimilar materials. Our company has the following...