New ReleasesPage 5

arrange in order

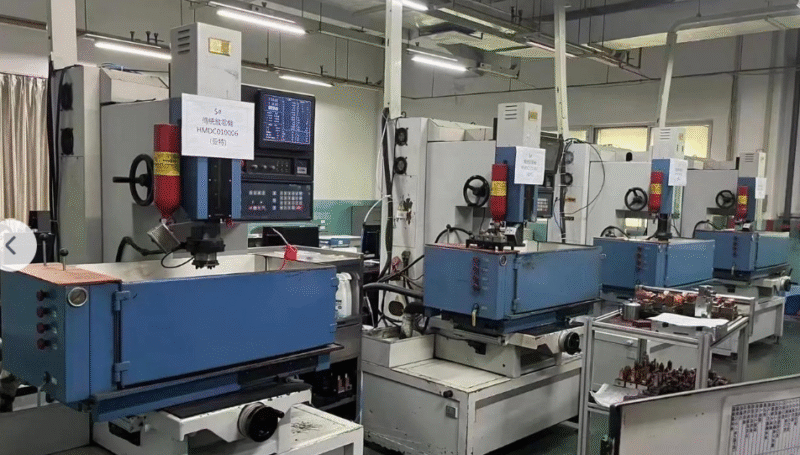

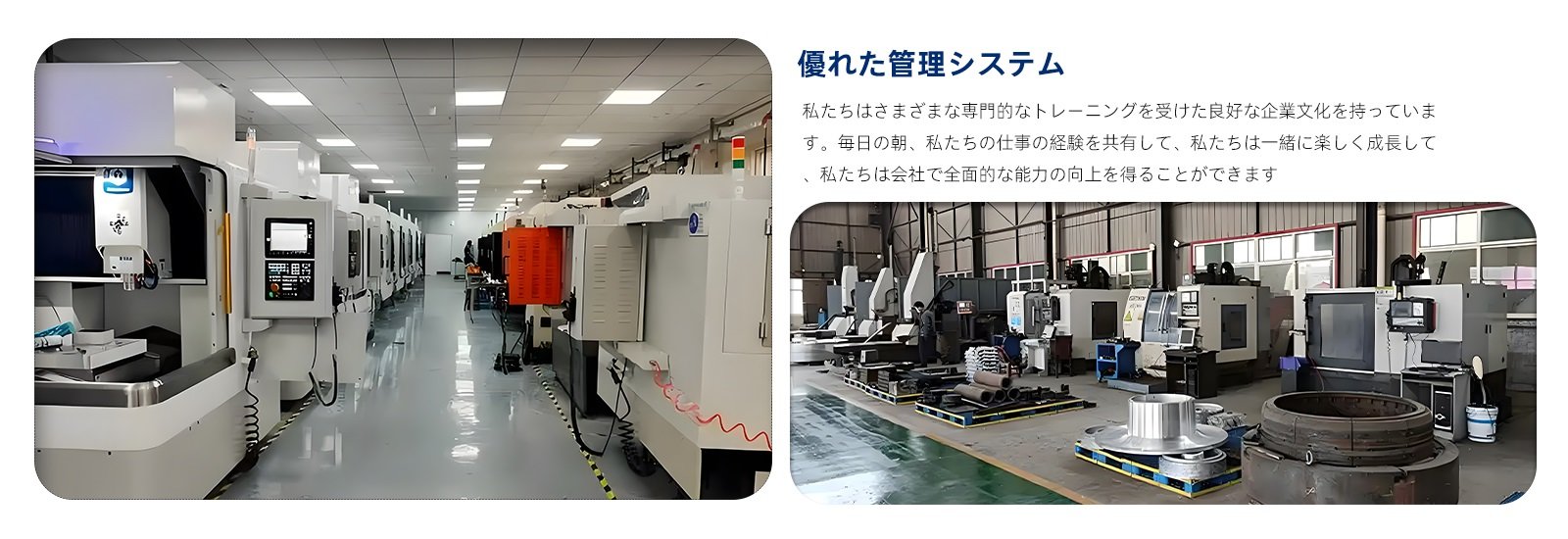

How to ensure machining accuracy? Understanding tolerances, surface roughness, and quality control processes.

Precision – The Lifeblood of Modern Manufacturing In the intensifying competitive landscape of manufacturing, machining precision transcends mere technical metrics to become a direct embodiment of a company's core competitiveness. From micrometre-level surgical instruments to nanometre-level semiconductors...

Aluminium and Stainless Steel – Properties and Challenges of Different Metals in Precision Machining

How Material Selection Determines the Success of Machining In precision machining, material selection is not merely a cost consideration but a core factor determining component performance, machining efficiency, and final quality. Aluminium alloys and stainless steels are the most...

Common Rivet Welding Methods and Case Studies in the Repair and Modification of Mechanical Equipment

Repair Welding – The Art of Reviving Machinery Throughout the extended lifecycle of mechanical equipment, wear, corrosion, fatigue cracks, and even unforeseen damage are inevitable. Direct replacement of entire machines or large components is often...

Enhancing Production Efficiency and Consistency through Automated Robot Rivet Welding

Amidst the wave of automation, the rivet welding revolution As global manufacturing transitions towards Industry 4.0 and China's "Made in China 2025" initiative, rivet welding processes—historically reliant on human skill—are now undergoing a transformative shift driven by automation...

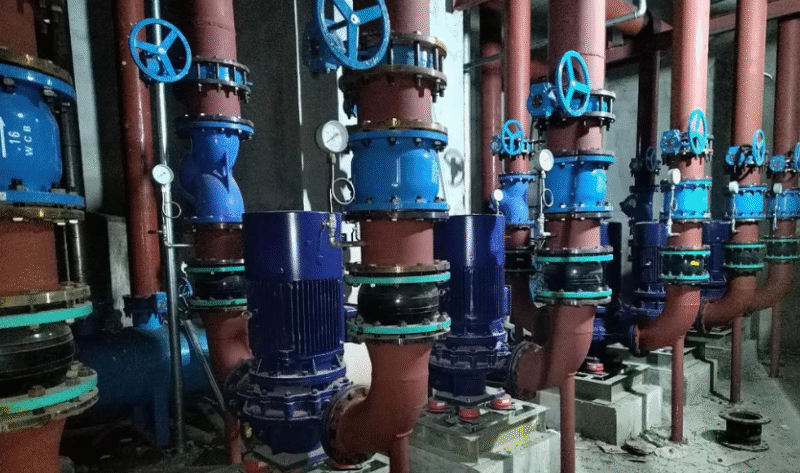

On-site Rivet Welding Techniques and Safety Standards for Pipe Installation and Repair

Special Challenges in On-Site Rivet Welding Pipework Pipework installation and repair frequently encounter constraints such as limited space, complex environments, and tight schedules. On-site rivet welding technology resolves these challenges...

How to Select a Reliable Aluminium Alloy Rivet Welding Service Provider? Six Evaluation Criteria

The Importance of Selecting an Aluminium Alloy Rivet Welding Service Provider Aluminium alloys are widely utilised in sectors such as aerospace, automotive manufacturing, and shipbuilding due to their characteristics including light weight, corrosion resistance, and high strength.

How to Select a Reliable Aluminium Alloy Rivet Welding Service Provider? Six Evaluation Criteria

The Importance of Selecting an Aluminium Alloy Rivet Welding Service Provider Aluminium alloys are widely utilised in sectors such as aerospace, automotive manufacturing, and shipbuilding due to their characteristics including light weight, corrosion resistance, and high strength.

Technical Requirements for Riveting and Welding Processes of Special Materials in Pressure Vessel Manufacturing

The Crucial Role of Pressure Vessels in Rhodium Welding of Special Materials Pressure vessels, serving as core equipment in sectors such as energy, chemical industry, and aerospace, play a vital role in ensuring production safety and environmental protection through their safety and reliability.

What is the calculation of machining input? Factors affecting the price of machining10

When you receive a machining quotation, have you ever been puzzled: how is this price arrived at? Why can the price of two parts that look similar be several times different? Transparent and reasonable quotation is the basis of trust and cooperation. This article will completely open the machining quote "black box", detailed...

Rotary disc machining, flues machining, drilling machining, and general machining engineering for mechanical machining are explained.

The world of machining Rotary disc machining and Flatbed machining is a world of snazzy "weapons" that make it possible to shape materials with precision. Rotary disc machining, Flatbed machining, Drill machining, Grinding machining, and others are available outside of the specialist...

.jpg)