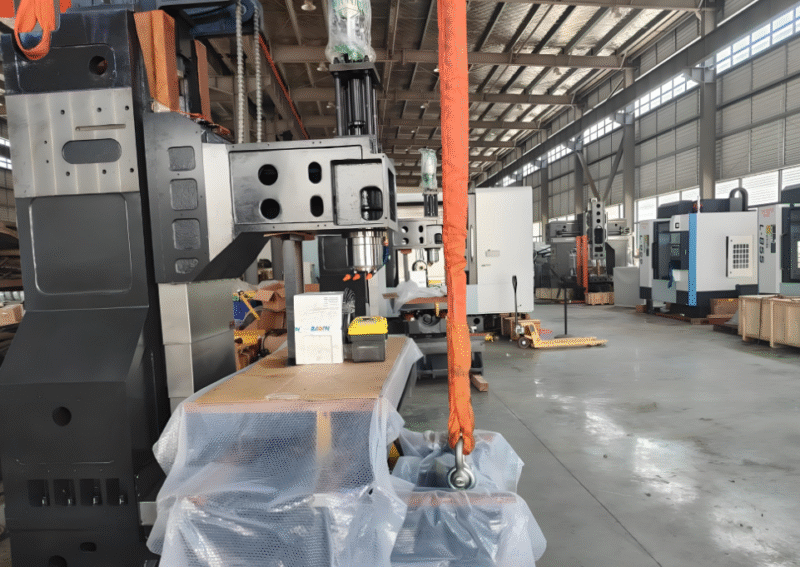

High QualityMachiningThis chronicle of the birth of part engineering explains the internal viewpoints of the factory, operation manuals, tool management, inspection of initial products, project management, and other key aspects of the conceptualisation of the project, as well as the strengths of quality management by professional experts.

![图片[1]-加工工程仕様の要件解説:高品質部品を支える生産管理ガイドライン-大連富泓機械有限公司](https://jpdlfh.com/wp-content/uploads/2025/12/QQ20251002-202341-800x497.png)

Elements of a Processing Profile: Workplace Standards for "Standard" to "Action" Turnaround

Hajime: "After the customer's clear "Prospecting Requirements" are elicited, the interior of the plant is recognised as a standard in terms of the aspect of the Prospecting, and the standard is confirmed. This is a company that relies on the internal 'engineering specification. '

I. Default in Prospectus Specification and Prospectus Elements

(Requirements and "goals" set by customers, internal "methods" and "rules" established in the factory based on specifications and goals achieved)

II.Concrete Specification Request System

1.Written specifications: Work Instructions (WI) and Engineering Card

(Definition of Staples, Parameters, Towers, and Inspection Frequency by Project)

2. Management of equipment and tools

(Periodic maintenance and calibration of machines, taking of tools, judgement of consumption and basis of exchange)

3. Quality Management Benchmarks

(1st to 3rd inspection system, frequency of inspection, confirmation of final product, correction of game)

4.サイト 5S and safety management standard

5. Management of unsuitable products

III. Keys to the practical application of the norms: record-keeping and travaux préparatoires

(Actual performance of standardised record paper: engineering card, inspection record, machine chart)

Fourthly, we guarantee the quality of our products for the final time.

(Theoretical chain: The stability of the product is guaranteed by the customer → The stability of the product is guaranteed by the consistent quality → The consistent quality is guaranteed by the suitability of the customer's requirements)![图片[2]-加工工程仕様の要件解説:高品質部品を支える生産管理ガイドライン-大連富泓機械有限公司](https://jpdlfh.com/wp-content/uploads/2025/06/QQ20250627-201220-800x650.png)

Conclusion on Strong CTA: [Prophylaxis and Transformation

"We understand the international standards for mechanical processing programmes, and we have the ability to practice the requirements of the customer's castle mills in accordance with our company's specifications. The quality of the system is really good, and if necessary, we will ask for a typical engineering specification of the company's services, and we will also ask for a lightweight welcome to the company."

YOKUARU QUESTION

"What exactly is inspected in the inspection of a single-form product? (Answer: All important dimensions, shape tolerances, surface finishes, and engineering elements are checked and recorded in the drawings and measurement data.)

"The machine workshop is suitable for the purpose of holding the Kadoka?" (Answer: ISO9001などの質質ネジメントシステムの認證を受けているかどうかを尋ね、場を視して書類を記録すればよい)

No comments