SMARTPrecision MachiningTrends and Future Prospects of State-of-the-Art Technologies

I. On Hajime: A New Era of Pantheon

Today, we are at the beginning of a new revolution in precision machining. While traditional machining methods are approaching their physical limits, the integration of artificial intelligence, digitalisation and green manufacturing concepts has led to the redefinition of "precision" through the powerful use of next-generation superstructure technology, and has given a new impetus to the high-end manufacturing industry.

II. The Future of Contextualisation

Intelligence and Digitalisation

AI-supported machining: The advanced grinding wheel has broken down the conventional machining paradigm with the Intelligent Clamping System. With the integration of ultra-high precision centers and the Realtime's AI analysis module, the machine collects tens of thousands of data (grinding force and vibration) per second, measures the tool wear with the use of a digital platform, and corrects for the Realtime's proximity parameter, while maintaining a very low level of machining variations (0.2 mcron). We have been able to control these changes in the process.

Digital Technology and Intelligent Solutions: Digital Technology is a new tool for optimising precision machining processes through the deep integration of Atomic Rebel Surface Analysis and other technologies2 . At the same time, the physical simulation of cutting processes based on Vigorous Data and Digital Technology will facilitate the transformation of traditional machining processes into Intelligent Solutions. The Vega System facilitates the change of traditional mechanical processing and integration services, and realises the integration of the basic data of the programme into the integrated application.8 The Vega System also facilitates the change of traditional mechanical processing and integration services.

Limit of accuracy

In the battlefield of nanoprecision, technology is now advancing. For example, the latest ultra-precision grinding discs have been developed to meet the requirements of the optical system of the TPRISGRAF, and the surface accuracy of complex free-form surface sylicones is as high as 0.15 μmcr PV (peak-to-valley-2) with the help of the techniques of the クローズドループフィードバック of the laser negotiation table, and the 0.05 μmcr ENGレード of the é-ÁBELIGNING SPINNINGDL. The industry has succeeded in achieving a surface accuracy of 0.15 micron PV (peak-to-valley)-2. All rights reserved. By 2030, we will be able to surpass the 1nm wall accuracy of engineering machining, and we expect to achieve the same by 2030.![图片[1]-智能精密机械加工:前沿技术趋势与未来展望(未来的精密机械加工将是一个多技术维度深度融合的领域)-大连富泓机械有限公司](https://cndlfh.com/wp-content/uploads/2025/10/QQ20251002-202005-800x719.png)

Greene's Continuous Possible Manufacture

In order to achieve higher accuracy, we have been actively involved in the manufacture of Greene products using our Spherical Finish technology. In the manufacture of medical implants (artificial joints, etc.), the innovative low-temperature cooling and microlubrication technology has maintained the surface roughness of 0.03 mcloin, drastically reduced the consumption of grinding fluid by 92%, and drastically reduced the generation of chemical wastewater-2. This is an indication of the continued possible development of the precision machining field.

Automation and Flexibility

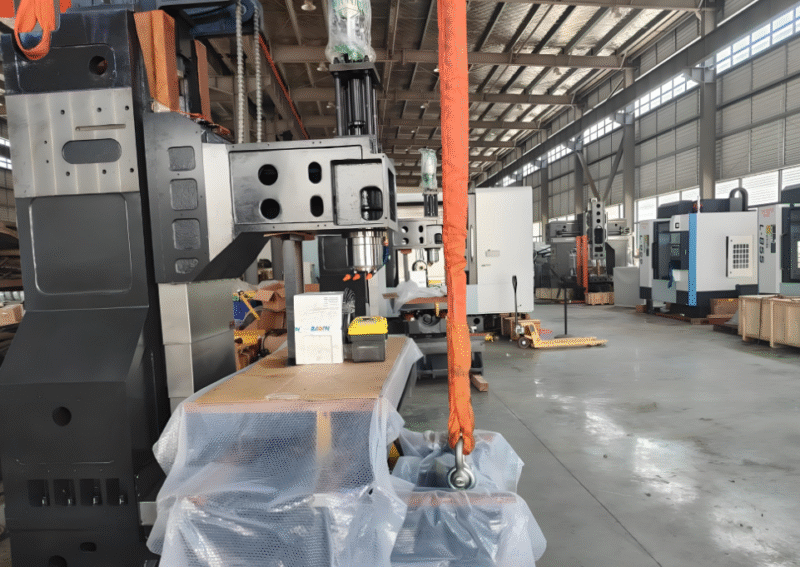

For the machining of complex structural parts (special carriages, aerospace gas ballburdies, etc.), the combination of a robot machining system and 5-axis CNC machining technology has effectively solved the problems of machining deformation and quality control of difficult-to-machine materials, such as the machining of barreling, grinding, and other machining processes. We have automated the production of high-efficiency, high-precision fabrics by using robotics, hydraulic pressure, and other automated units-10.

III. Future Prospects

The future of precision machining includes the deepening of the machining stability of nanoscale in the vertical direction, the expansion of complex functional modules in the horizontal direction, the expansion of grey matter in the vertical direction, and the deepening of the integration of multiple technological sub-divisions in the entirety of the Rafflesia system(2). As a result of this technological revolution, precision machining has become a central part of the high-performance manufacturing industry.

IV. CONCLUSION: Change, change, change, change, change

All the participants are actively understanding and applying the technologies of smoothing, gluing, and ultra-precision manufacturing, as well as pursuing the development of the future of Coa-Construction.

Cole・Tゥ・Akushion

Is your organisation prepared to deal with the next-generation finisher technology issue? We will be able to use the hand-held technology in advance of the times. The company's smt processing software is available for viewing, and the company's software is available for contacting today, as well as for taking photographs of future production.

No comments