This is a specialised account of "Mechanical Processing in China" and "Machinery Manufacturing in China".

Taito: Mechanical Processing and Machinery Manufacturing in China: Enjin and Innovative Forces in Grobling and Sapling

help China's machining and mechanical engineering industries, its core strengths, technological innovations, and the way to achieve high quality of service are all to be viewed. Leave a comment on "Meido-In-China" is an important service provider in the field of precision parts and complex machines.

Chronicle of the Lord

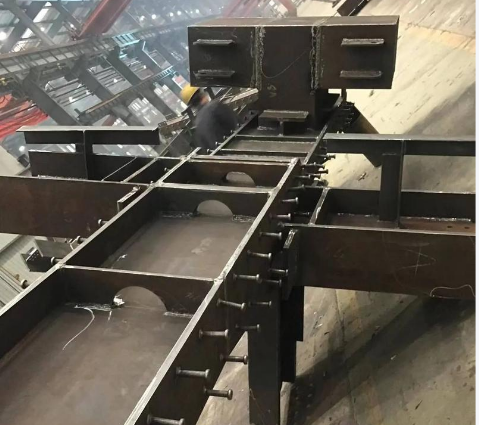

In the midst of the growing industrialisation of the globe, "China Machinery Processing" and "China Machinery Manufacturing" have been under-utilised as well as under-utilised as well as under-utilised. With decades of rapid development, large-scale industries, rising technological standards, and the superiority of the SIP, China has secured its position as one of the world's core manufacturing bases. Precision kastamaji parts and complex devices, China's machining and manufacturing capabilities have had a significant impact on the world's industrialチェーン.![图片[1]-中国机械加工与机械制造:全球供应链的引擎与创新力量-大连富泓机械有限公司](https://cndlfh.com/wp-content/uploads/2025/07/QQ20250720-185627-800x550.png)

I. Mechanical Processing in China: A Synonym for Precision and Efficiency

"Machining in China" is a very broad and limited field:

-

Rotary disc machining, flues machining, drilling, and grinding: The basic engineering of machining is very important in China, and we are proud of the high level of sophistication and popularity, the wide range of metallic and non-metallic parts that can be applied to a wide range of complex and standardised parts, and the wide range of non-metallic parts.

-

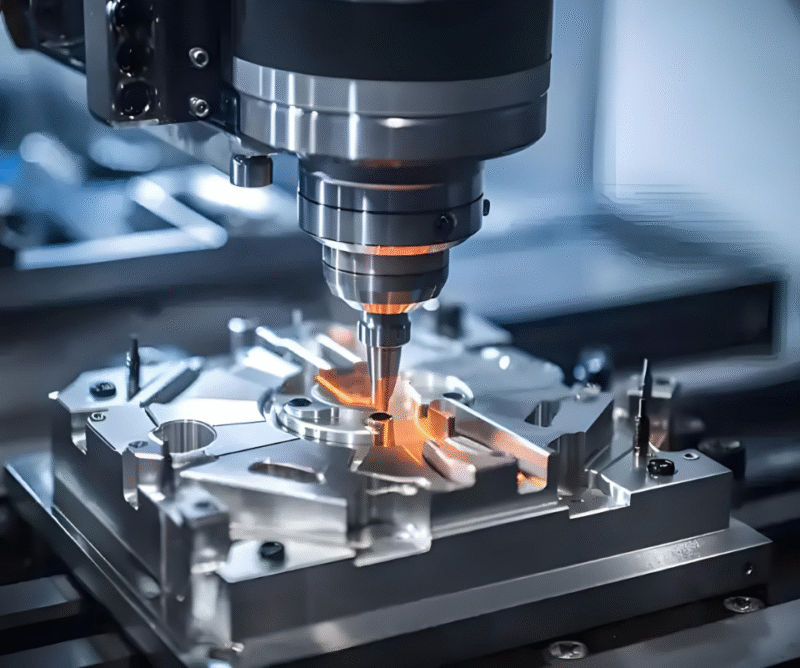

CNC machining: This is the modern "China Machine Tool" concept. China has the world's largest number of CNC machines (machine centers, trench centers, wireless kits, laser cutters, etc.), and the market for hydraulic, mechanical, and rotary machines is expanding. Powerful CNC capabilities for mechanical processingHigh precision, consistency, complexity and efficiency..

-

Special processing: EDM, Laser Processing, Wound Jig Processing, etc., are suitable for processing of difficult-to-process materials and special structures.

-

Sheet metal processing: It is widely used in the manufacture of synthetic leather products and structural parts.

The strengths of China's core in machining are as follows:

-

Huge キャパシティとスケールメリット: The price of a single unit has dropped dramatically in response to the large number of notes.

-

Establishment of a service centre and a network: The raw materials (steel, alloys, special alloys, etc.) and the tools, jigs, and equipment maintenance are available, and the supporting industries are extremely mature, easy to adjust, and quick to respond.

-

Skilled labourer's pl and skills upwards: Competition for excellent human resources has become more intense, and China has improved its system of vocational training and skills recognition for skilled labourers.

-

Costs and effects: The overall costs (manpower costs, compensation for equipment reductions, management costs, land use costs, etc.) are such that many advanced countries are more competitive than others in terms of maintaining quality.

-

Quick response and softness: A large number of companies have been able to quickly adjust their production labels by combining small roto and multi-product kastmasters into a single package.

II. Machinery Manufacturing in China: Basic Equipment and Hurdles, Smarters, and Manicure in China

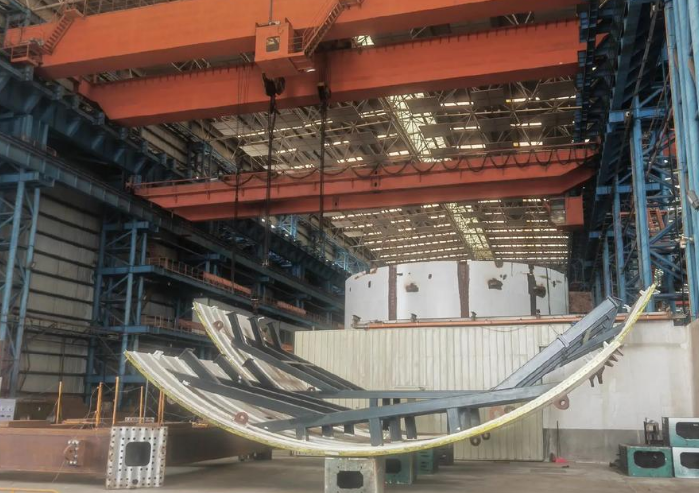

China Machinery Manufacturing" and "よりマクロな概念で、さまざまな機機械加工技術、組立工程、システムエンジニアリングを駆用した機設備一式、産ライン、産業システムの製造を指す。 This section contains the following information:

-

General machine building: Pump, Balboa, Conpresseur, Vegetarian, Gallery.

-

Manufacture of special machines: Construction machinery, agricultural machinery, fibre optic machinery, printing machinery, food processing machinery, plastic machinery and other industry-specific equipment.

-

Manufacture of Work Machines China is a major producer of working machines, supplying and exporting them domestically.

-

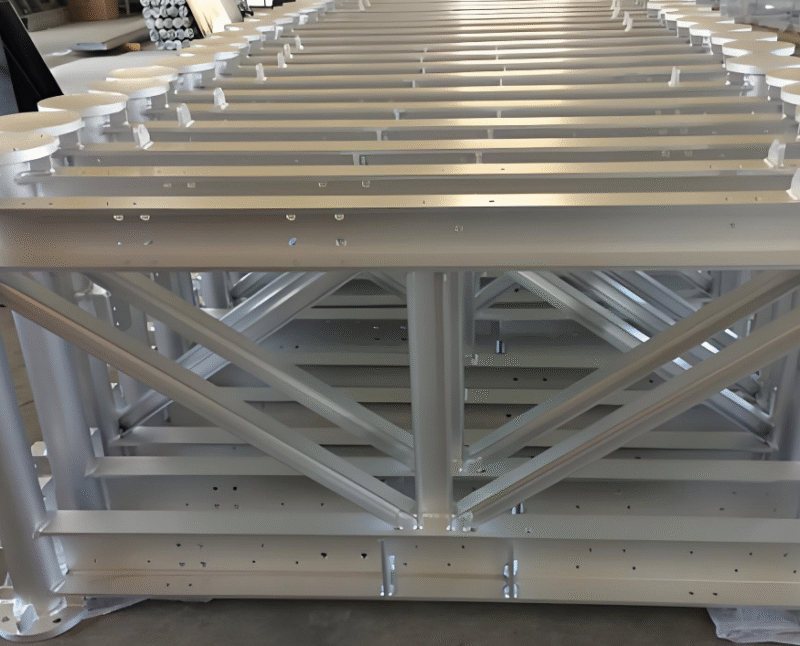

OTME and IntelliJet machines: This is the focus of the current development direction of "Made in China", including industrial robots, automated production labs, intermediate test equipment, and logistics and warehouse automation systems.

-

Manufacture of Major Components We provide precision components for domestic and overseas hydraulic equipment (aerospace, energy, medical equipment, etc.).

Evolution and Priority of China's Machinery Manufacturing Industry:

-

The leap from "quantity" to "quality": At the beginning, we were in the centre of royalty and OEM, but now we are in the process of transitioning to a new generation of hobbyists, independents, and insiders, and we are fully committed to our work in the field.

-

Government Battle Support In the national strategy of "Meidu Inchiina 2025", the key development areas and areas to be considered for the development of high-capacity CNC machines and robots, advanced railway equipment, energy-saving and new-energy automobiles, and electric power equipment, as well as the investment of enormous resources, have been clearly defined.

-

Technological innovation is the driving force: Geo-companies and research institutes are investing in research and development in the fields of material science, design software, control systems, and 3D printing and shaping (3D printing and shaping), and are significantly strengthening their capabilities in this field.

-

Complete Industrial Ecology: The basic research and development, design, manufacture of parts and components, and the assembly and distribution of all machinery, as well as the development of a complete industrial chain, have all been formed.

-

Powerful output capability: Machinery and equipment made in China are sold in the world market, especially in countries on the road to development and emerging economies, with their cost-effective and high quality.

![图片[2]-中国机械加工与机械制造:全球供应链的引擎与创新力量-大连富泓机械有限公司](https://cndlfh.com/wp-content/uploads/2025/07/QQ20250720-185504-800x528.png)

III. Methods of Seeing Mechanical Processing and Manufacturing Patterns in China on a Firm Basis

It is very important to select "Chinese Machining" factories and "Chinese Machinery Manufacturing" companies with high quality in order to meet many Chinese service providers:

-

News: Product specifications, quality standards (ISO9001, AS9100, IATF16949, etc.), quantities, estimates, and standards are specified.

-

A detailed survey:

-

B2B Plateforms in Action Aribaba, Intana, Meidu, In, Chaina, etc., and carefully consider the information.

-

Industry Views: We have participated in large-scale exhibitions such as the China International Industry Expo and the Guangzhou Trade Fair, and have taken part in the exhibition and the direct contact.

-

Pro Recommendations and Audits The industry associations and consortiums, as well as the third-party plant inspection service providers, have been able to access the information and conduct the qualification audits.

-

-

Critical Evaluation:

-

Technical Skills: We will adjust the equipment, processing accuracy, engineering and machinery strength, and the experience of the company (especially the performance of similar products).

-

Quality System: We have learnt about quality management programmes and revolutions by confirming our quality certification.

-

Production Management: Evaluate the production plan, Sapling management, and on-site management of the company (video workshop inspection is possible).

-

Comunicaciones y servicios: We will examine the applicability, language ability, technical communication skills, and problem solving skills.

-

Conplicação: The Environment, Labour and Other Constituents are discussed here.

-

-

The trial of the service and the small batch: The most direct way to try out the actual strengths of a surrogate is to rely on the work of the sampler before deciding on a large mouthful of notes, and to rely on the work of the sampler and the small batch.

-

To conclude a definitive contract: The conditions of the technical contract, quality standards, payment periods, payment methods, protection of intellectual property, and liability for breach of contract are clearly defined.

IV. Prospects: Issues and Opportunities

The future of China's machining and manufacturing industry is full of challenges and challenges:

-

Chansudan: The high level of industrialisation (Intelligent Manufacturing, Green Manufacturing), the expansion of the domestic market, the "One Belt, One Road" project, overseas market opportunities, and technological innovations, are also being pursued.

-

Chirenji: The high cost of manpower, the shortage of human resources in the Netherlands, the need for conventional technologies (such as the high-end CNC system and the precision centre), the intensification of international competition, and the uncertainties arising from the reorganisation of the Global Service Centre (GSC).

Judgement

"China's machine tooling and China's machinery manufacturing have surpassed each other in terms of "low-cost" and single-unit repertoire. It isStrong Manufacturing Base, Upwardly Mobile Technical Capability, Highly Advanced Suprai Chain and Ecosystem, and Groovy Barry Chain Intentions. China is an important source of supply for a wide range of cost-effective machinery parts and equipment to meet the needs of the world's most demanding industries. The key to success is to deeply understand the complexity of the market, to apply effective strategies, and to manage and manage the ports in a way that is truly superior in terms of technology, quality assurance, and value judgement. China's machinery industry has been accelerating the path of high-quality development in the Intelligent Industrial Zone, and its influence on the world has been profound.

No comments