Stainless Steel Rebate Joining Technology for Thin Plates: Reliability of Precision Metal Joining in the Patterns

Lightness, strength, precision are sought after in today's industry. Thin Plate Stainless Steel Rebelling Technology is used in many industries, such as nuclear engineering and nuclear engineering. The necessity of medical equipment's delicate parts, the important connection part of automobile exhaust system, and the stubbornness of electronic equipment in Haiyendo has changed. The reliability, efficiency, and aesthetics of the metal bonding soldering system are excellent. It is also a proffered product. Thin Plate Stainless Steel Rebreather Technology Split Coat and Barrier.

What is the importance of Puzzle Rebate Technology for Thin Plate Stainless Steel?

Stainless steel sheets (usually 0.5mm to 3.0mm thick) are characterised by their excellent properties. It has excellent features such as food resistance, high strength to weight ratio, hygienic and simple handling, and a moderately attractive appearance. It is widely used:

Automobile Industry: Exhaust system parts, センサーハウジング, Trim parts, New Energy Battery Park parts.

Medical Equipment: Surgical Instruments, Machine Causes, Trolley Frame, Precision Machineハウジング.

Food & Beverage Processing: Workshop, Container, Paip, Conveyor.

Electrochemical products: Synthetic leather netting, Embroidery, Precision Blankets, Conecta parts.

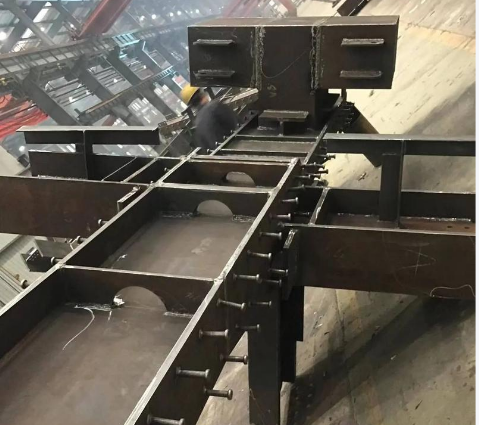

Industrial Machinery: Shields, Pannels, Ventilation Dockets, Precision Parts.![图片[1]-薄板用ステンレス鋼リベット接合技術サプライヤー:精密金属接合の信頼できるパートナー-大連富泓機械有限公司](https://jpdlfh.com/wp-content/uploads/2025/07/QQ20250718-201719.png)

The joining of thin plates of stainless steels is carried out with certainty. Rebending technology (combination of rebending and fusing lengths) is uniquely suited for this purpose:

Soldering problems: Soldering of thin sheets is very much affected by the problems of distortion, barring, and large heat effects. Rebate bonding is a method to reduce the heat input efficiently, and the distortion repercussions are greatly reduced by the combination of mechanical joining (rebate bonding) and partial bonding.

Higher joint strength and tightness: Precision bonding (laser bonding, machining, plasma bonding, resistance sponge bonding, etc.) is an important part of the strength, rigidity, and gas/liquid tightness of the joints, as well as an important part of the stressing process, and it is necessary to compensate for this by using syringe.

Applicable to complex structures and dissimilar materials: In cases where it is necessary to join complex structures or stainless steel to other metals (alminium, copper, etc.), Rebett Soldering is soft and highly reliable.

The efficiency and beauty of the baranas: the revolving stopper can be quickly assembled, and the partially solved joints can be used to satisfy the beauty requirements of high-quality products.

Important Values of Thin Plate Stainless Steel Rebelling Technology for Professional Service Providers

In cases where the necessity of precision thin sheet steel reinforcement is faced directly, experienced and skilled operators should be selected. Bundle of Vertical Carbons:

In-depth technical expertise and knowledge of the programme:

We offer a wide range of thin plate steels with excellent resistance processing (e.g., hydraulic resistance, pulleability, and security piasture resistance) and precision welding programmes (laser welding, maiklovim and plasma welding, resistance sponge welding, and TIG welding).

We have a deep understanding of the machinability and solubility of various types of stainless steel (304, 316, 430, etc.).

We have made a lot of efforts to prevent deformation, to prevent barring, and to ensure the accuracy of the process of thin plate processing, as well as to develop programs and projects.

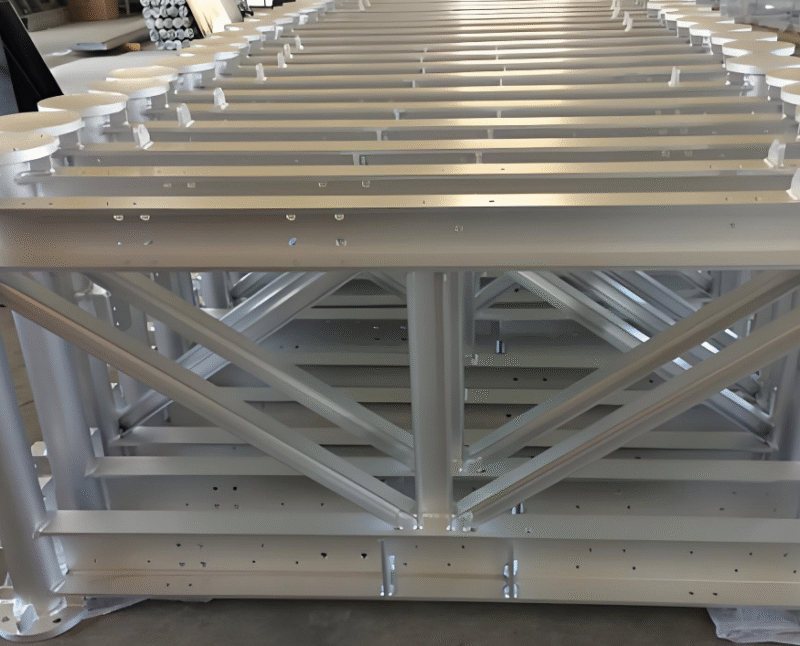

High level of equipment and proximity control:

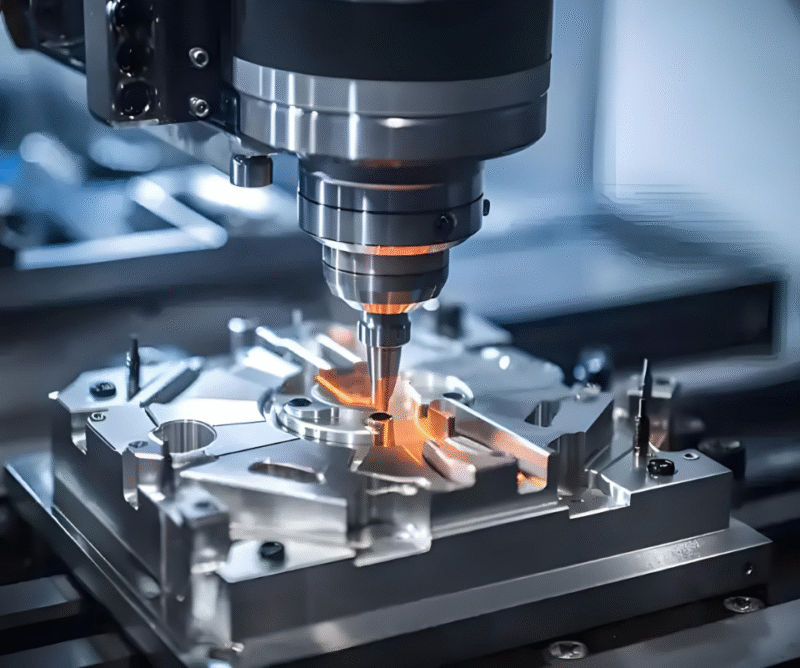

High-precision CNC laser cutter, precision stepping machine, automatic robot, and highly efficient welding power supply (high-precision laser welding machine, mike robot welding machine, etc.) are installed.

The high accuracy and continuous quality of each product is guaranteed by the SPC and the ISO 9001 quality assurance system, and the reliability of each product is consistently high.

Powerful design and engineering capabilities:

In the early stages of product design, we recommend the optimisation of the design of the succeeding structure by providing the following capabilities: Design for Manufacturing (DFM), upgrading the performance of the product and reducing the cost.

We can provide engineering and jig design for customer's design and connection.

Integrated Precision Manufacturing Services:

We will provide you with the information you need. Precision antenna cutter (laser cutting/panning) -> Forming (curved/stainless steel) -> Rebent junction -> Surface treatment (opsonic, electrolytic grinding, sandblast, etc.) -> Precision cleaning -> Structural quality control work to rationalise the customer's service.

Quality control:

The use of high-precision inspection machines (secondary image measuring machine, coordinate measuring machine, non-breakage inspection machine for welding, etc.) for strength, depth of welding, quality of welding, inch tolerance, and all-round inspection of appearance.

Quick response and soft production:

The requirements of the market of small quantity, variety, and short period of time with soft response capability are the rapid recovery of the customer's products in the strong market.

Coacompitance: Trusted Patterns

Root-strengthened ファンとして thin plate Stainless steel リベッティング technology the division of the field of the スペシャリスト・サプライヤーとして, the private Tachiban to take the next this and the combination of んでいます:

We provide the most advanced Solids for the research and development of cutting-edge equipment (such as the fabrication machine, the precision salver consolidation machine, etc.) and the project development, and we will continue to invest in overcoming the technical barriers to the joining of thin sheets.

Guarantee of excellence: We have established a comprehensive quality management system to ensure that our products meet the expectations of our customers, and that we are able to guarantee the excellence of our products.

Customer's Needs: We understand that the customer's appliance and piñonports have a high level of cost-effectiveness and reliability, and that we provide a reliable connection to the pipeline.

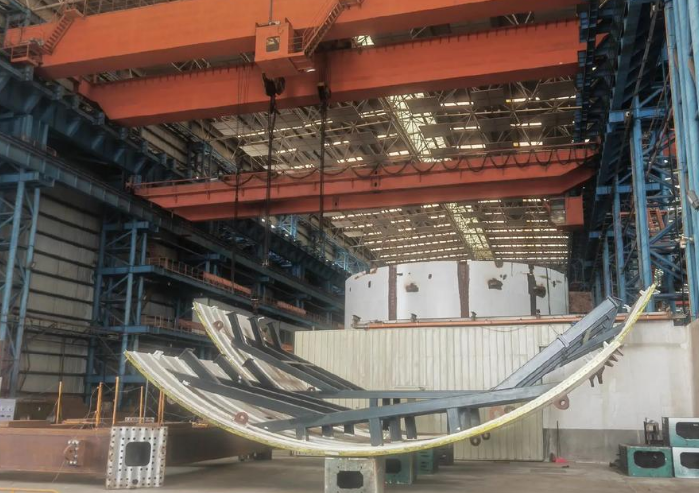

Optimisation of value offerings: Efficient manufacturing programmes and service platforms to reduce time to market and reduce total cost of ownership.![图片[2]-薄板用ステンレス鋼リベット接合技術サプライヤー:精密金属接合の信頼できるパートナー-大連富泓機械有限公司](https://jpdlfh.com/wp-content/uploads/2025/07/QQ20250718-201839-800x694.png)

SERVICE PROSPECTS

Requests for information on: product specifications, material specifications, performance specifications, and estimates are subject to our deepest understanding.

The design of the project and the insights into the DFM concept are based on the project strategy, the analysis of the possibilities, and the insights provided.

Make and Verify: Design, service, and quality can be verified by making the service quickly.

Batch production and programme monitoring Confirmation of the programme is carried out on a strict basis, and the entire programme is monitored for important quality points.

Complete Quality Control and Nano Period Compliance: The final and strict inspection is carried out in order to ensure the integrity of the product.

Previously, we have provided you with a full range of services and technical reports.

Wide application field

Our Precision Thin Plate Stainless Steel Rebate Technology is applicable in successful applications:

Automotive Ecizonto Manihot, Sensors Blanket

Medical Endoscopic Parts, Surgical Instruments Jewelry, Machine Hanging

Food Containers, Pipes and Flat Connections

Service, 5G Machine, Precision Electronic Mobility

Industrial Instrument Panele, Syringes, and Exchangeable Parts

What do you mean by "leave a message"?

The reliability of Anata's project for Stainless Steel Plate is high, it is correct, it is strong in terms of the beauty of the joining technology, it is rich in experience, and it is the key to the success of the thin plate Stainless Steel Revetment Technology Suprayrayraya.

We are confident that we can make strong, accurate, and competitive products in a single step, and that we can use our excellent expertise and bonding technology to make these products!

[Your Company Name] - Specialised Solids for Precision Rebelling of Sheet Metal Stainless Steel

Optimised Hinter (Reference).

Taito Nucleus and ケーワード are included.

The main items are the natural and complex groupings of the core and outer work (thin plate steels with rebel technology, steels, rebel welding technology, bandage) and its sub-groups (precision metal joining, steels, rebel welding, cartomizers and soldering, precision manufacturing services). We have included the industry terminology related to Aplications and Sinaloids in this section.

Clearly constructed. The small insights (H2, H3) are organised in a way that they can be read and interpreted, and the search engine can be understood.

The value of a container. Answer to your questions (Puzzle is important?) What is the value of the service? Service programme?) Provide practical information.

コール・トゥ・アクション (CTA). Endeavour to promote Tsunagari.

Multimedia Scholarship (Scholarship). The main contents of this publication include the core of the journal and its contents, and the description of the theme of the website is written in about 155 characters. For example, the "Profiles of Stainless Steel Rebent and Welding Technology Service Plaza" provides a highly reliable and accurate welding method called "Soligon". It can be used in the automotive, medical, electronics and other industries to solve the problem of deformation of thin sheet welding. Kastamiza's services and strict quality control."

If the ALTAG record of the image is illustrated, the associated keyword in the ALTAG can be confirmed (e.g. "Precision Thin Stainless Steel Lazer Soldering Service", "Automatic Stainless Steel Rebent Manufacturing Lanes").

No comments