Control of change in shape of precision welding: the key to quality and accuracy

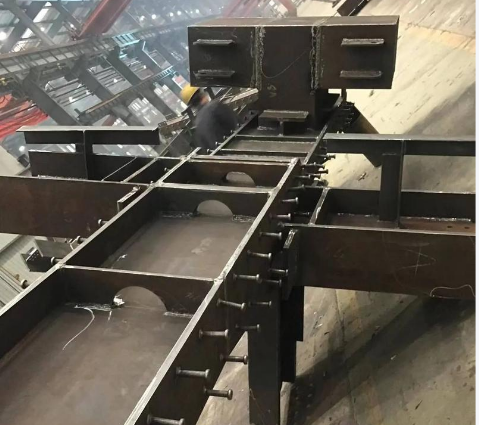

Manufacturing division that seeks extreme precision and reliability.Precision SolderingThe quality of the welding process is directly related to the success of the product. Avoidance of thermal stress in the bonding process.Change in shape and controlThe problem of back control over ingenuity is at the heart of the problem. The deformation of the product is related to the impact on the accuracy of the dimension and the assembly performance of the product, the weakening of the structural strength, the deterioration of the product, and the high cost of the product. We have analysed the deformation of this product in terms of its efficiency.Precision Soldering Crooked MethodWe are committed to ensuring the technological superiority in manufacturing industry.![图片[1]-精密焊接变形控制方法解析:提升质量与精度的关键-大连富泓机械有限公司](https://cndlfh.com/wp-content/uploads/2025/07/QQ20250713-202014-800x672.png)

I. Optimisation of the Prosperameter: Inhibition of Deformation in the Source of Development

-

Correct thermal entry control: With the use of low melting current and voltage, and the combination of fast melting speeds, the total heat added to the melting section and heat-affected section is greatly reduced. The Pulsar Soldering Technology (Pic/Bezel Current Control) is particularly effective in reducing the size of the melting tank and concentrating the heat source.

-

Sequence and direction of dissolution: The welding route is scientifically designed so that the heat generated can be dispersed equally and the local stresses can be counteracted. In general, we use the following methods: symmetric bonding (inward movement from the centre to both sides), degaussing (bonding in the opposite direction to the direction of degaussing), and screw bonding (broadening of the area of concentration of heat).

-

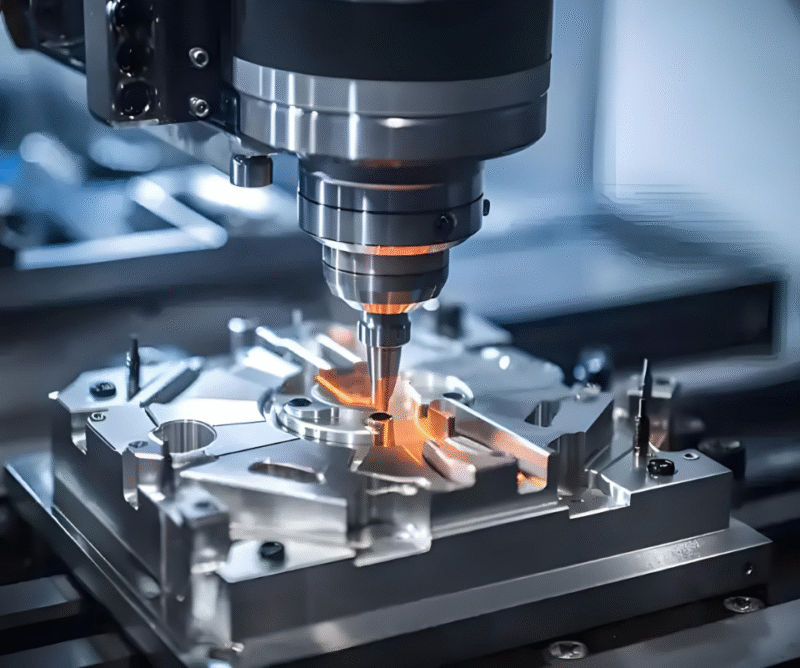

Application of efficient solvent bonding technology: TIG (Tangsten Intelligent Gas Shield Bonding), laser bonding, electronic beam bonding, and other high-energy density, low-heat-intake proxies are the most suitable for precision bonding with a significant reduction in distortion.

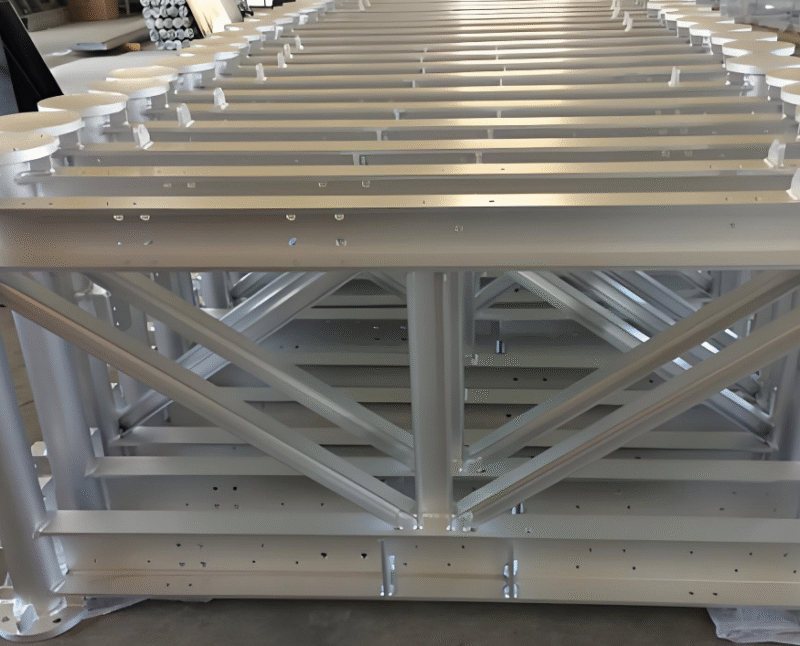

II. High-altitude tools and rigid body fixation: external forces constrained by deformation

-

Soldering Fixture Kastamas In the process of welding (especially thin parts and complex structures), special fixtures are designed and manufactured to secure the material to be processed and to resist the contraction force efficiently. In order to avoid the development of new stresses, it is necessary to pay attention to the rigidity of the fixtures and the appropriate configuration of the clamping ports.

-

The softness of the restraints by preventing the plastic seat from changing shape: Based on the prediction of the tendency to change shape, we prepare for the change of shape by reversing the direction of change before welding (reverse transformation method). Adjusting the possible adjustment of the frequency and speed of the sample is a good way to reduce the effect of shrinkage and to increase the power of the correct portion of the sample.

III. Structural Design Optimisation: Preventing Problems Before They Occur

-

Optimisation of the configuration of the joint and the joint: The structure design of left-right symmetry is given priority in the configuration of the fusion joints by the baranas. The number, length, and amount of fusion channels and molten metal are reduced. In the case of angular and renegative relay, the number of defective and less mutable bridges is preferred.

-

The material is combined with thicker materials: In order to achieve the best performance, we have selected a material with a small coefficient of thermal expansion, reasonably combined the thickness of different parts, and reduced the effect of deformation by uneven収縮がもたらす.

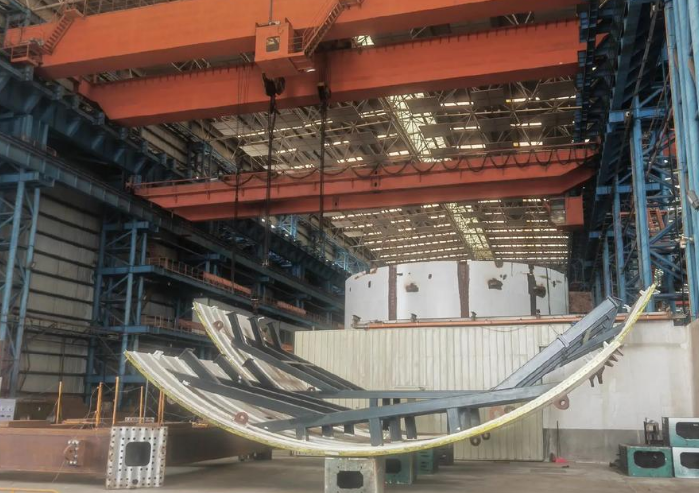

IV. Thermal Management Technology: Intelligent Adjustment of Temperature Field![图片[2]-精密焊接变形控制方法解析:提升质量与精度的关键-大连富泓机械有限公司](https://cndlfh.com/wp-content/uploads/2025/07/QQ20250713-201938.png)

-

Preheating and interlayer temperature control: In the case of thick plates or specific materials (high carbon steels, alloy steels, etc.), the cooling rate should be adjusted in order to reduce the residual stress. In the case of multi-layer bonding, careful control of interlayer temperatures is indispensable.

-

Asisto Cooling Technology: The use of water-cooled copper brocks, consolidated air, and special cooling agents, and the rapid cooling of the inner part of the welded part or the non-welded part in a localised manner (with attention paid to hardening and cracking disks) are effective in controlling the degree of heat stress.

-

Decentralised heat source approach: When the specific field (associated heat source) near the joint is heated simultaneously, the appropriate temperature match is made by eliminating the shrinking stress from the main joint heat source.

V. Corrections after dissolution: Minor corrections

-

Stress relief by heat treatment: Total passivation, partial passivation, stress removal passivation, effective reduction of residual stress, and improvement of stress deformation (especially for very high stability requirements).

-

Corrective technology for machines: The use of presses, jigs and special orthopaedic machines for the deformation of workpieces is possible in the cold room school and the hot room school (after heating pressure), for the deformation of a large number of workpieces, and for plastic deformation of a certain degree.

-

Vibration energy processing: The mechanical vibration is increased by a specific number of waves, the homogenisation and liberation of the residual stress is promoted, and the working speed is stabilised.

Offer: The key to unify the Aplicação to win!

Precision Soldering Crookedness ControlThe decision to rely on a single solution has been requested by Nigeria on a secondary basis.We select and combine the specific workpiece materials, structural characteristics, accuracy requirements, production conditions, and specific methods scientifically.. Optimised design and engineering before joining, parameter control during joining, heat management, strong fixation, and post-joining treatment are extremely important. This product is ideal for soft and flexible applications.The Law of Defining the Royalty by Changing Shape (変形制御法)Anata has made significant improvements to the following.Precision SolderingThe stability, accuracy, and reliability of our products are the result of our technology, and we are able to compete in the market with our customers.

Optimised Hints (For Your Information)

The kits are naturally assembled: The core and various tools (precision bonding, deformation control, bonding distortion, heating, residual stress, jigs and fixtures, etc.) are shown in this article, and the rational distribution of these tools is shown in this article.

Convertibles are valued in Oriental: This account provides practical knowledge of the techniques that have been constructed.

The structure is clear: To read yasuza, see the comments, the small comments, and the list.

ユーザー・インテント・マッチング: The content of the technical news of the search for the "Transformation Control Method of Precision Welding" is directly related to the content of the search.

Skeletal Velvet: Specific examples, comparison of deformation characteristics of different materials, application of numerical simulators for deformation prediction, etc., as well as additional contents are added.

No comments