High Strength Aluminium Alloy Rebent and Welding Processing in China: Technologies and Strengths to Reach the World

Lightweight, high strength, excellent performance for the modern industrial field is high strength Aluminium alloy aerospace, railway transport, new energy automobile, Haiyinde machine manufacturing industry. Core material. These materials are highly reliable and can be replaced by other structural components. Rebate and welding technology is particularly important. In this field, China has a deep tradition of manufacturing, absolute technological innovation, and a competitive advantage in the processing centre and the world.

Puzzle high strength Aluminium alloy?

Strength-to-weight ratio: The strength of the structure is maintained, the overall weight is greatly reduced, and the energy efficiency and performance (fuel efficiency of aircraft and the distance travelled by automobiles) are improved.

Excellent food resistance: Especially for aerospace and marine environments, it is resistant to environmental degradation and can last for a long time.

Good processability and formability: easy to manufacture complex structural parts by rebate, welding and other processes.

Excellent electrical and thermal conductivity: It is suitable for parts which are necessary for exothermic and electrical conductivity.

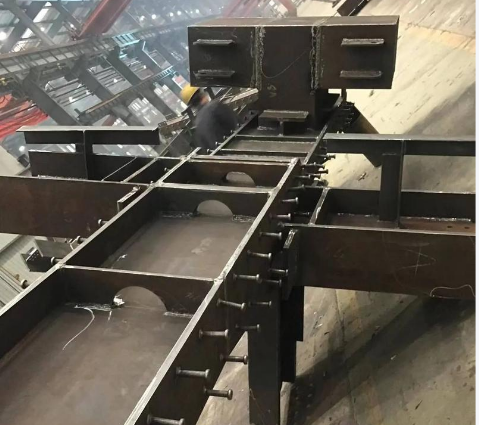

Rebate Bonding and Welding: Important Properties for Bonding of High Strength Aluminium Alloys![图片[1]-中国の高強度アルミ合金リベットと溶接加工:技術と強さで世界をリードする-大連富泓機械有限公司](https://jpdlfh.com/wp-content/uploads/2025/07/QQ20250706-201203-800x646.png)

Bonding of high-strength alloys is one of the core applications of these alloys. Chinese manufacturers have accumulated a wealth of experience and have reached international advanced level with the following major rebates and bonding programmes:

High level of welding technology:

Friction stir bonding: Suitable for special high tensile Aluminium alloys (e.g. 2xxx, 7xxx sizes). It can be used to avoid the defects in the soluble cohesion, high joint strength, low distortion, and low residual stress. It is widely used in aerospace fuel tanks and railway bodies.

Laser Welding and Laser MIG Composite Welding: High energy density, precisely controlled heat input, fast welding speed, low distortion, and suitable for precision parts and efficient production.

Transformable Polarity TIG/MIG Bonding: The acidic film on the surface of Aluminium alloys is effectively broken down, and high quality bonding systems are available, which are widely used in the aerospace industry and other fields.

Precision Resistance Spot Welding: Highly efficient for joining thin plates.

Precision Rebeting Technology:

The main mechanical joints of aerospace structures and the main mechanical joints of the aerospace structures are held at very high tensile strengths and severe breaking strengths. The Chinese manufacturer has expertise in automated equipment and strict project management.

Coatings: Adaptation to one-sided operation of samazanas (oopon, krozod, structuring, etc.).

Pressure relief: Provides a smooth and uniform surface on important parts of the exterior.

Core Strength of High Strength Aluminium Alloy Rebent and Welding Processing in China

Strength of Materials and Prospectus: Detailed study on the solubility and reinforcement properties of domestic and imported high-strength alloy grades (7075, 2024, 6061-T6, 5083-H116), as well as the development of optimal prospectus and sorbent.

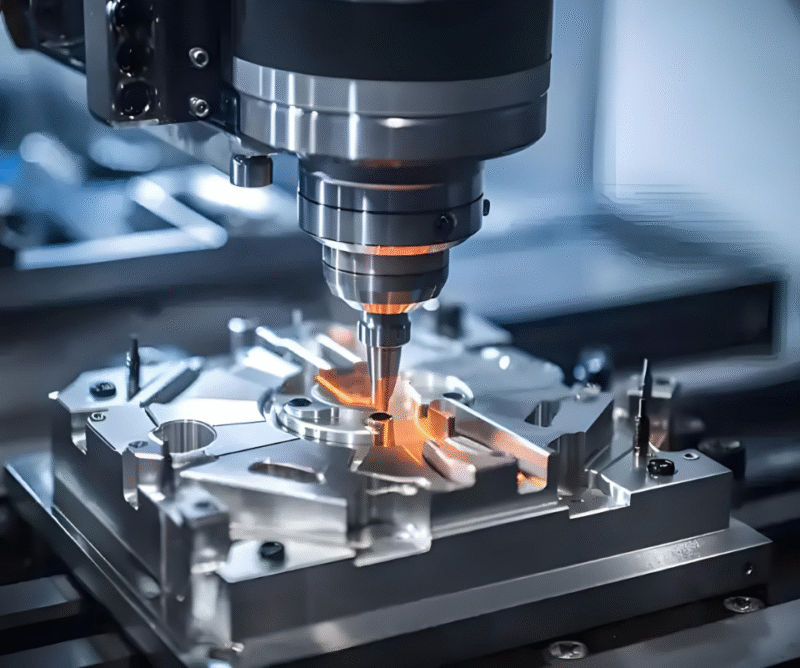

High manufacturing equipment: In order to ensure machining accuracy and efficiency, a large amount of investments have been made in automatic FSW equipment, high-precision laser welding systems, robotic welding systems, and CNC cavities and robotic systems in international top-class facilities.

Matured Sample Chain and Skewer Evaluation: We have developed a fully efficient industrial chain from the supply of high-quality alloy raw materials to the processing of precision parts and surface treatment (anodising and melting). The drastic reduction of costs and the shortening of reed tiles.

The quality control system: ISO/AS9100 and other international aerospace quality specifications are in general use, and high level NDT test methods (X-ray, ultrasonic, immersion test, etc.) are installed to ensure the reliability of each connection.

Continuous technological development and innovation: Universities, research institutes, and companies are working closely together to overcome the problems of connecting new materials and structures in a continuous process, and to promote the advancement of the programme.

The price and performance is a major advantage: the combined competitiveness of the Mead, In, Chain and Chain is outstanding, while ensuring top quality in the world.

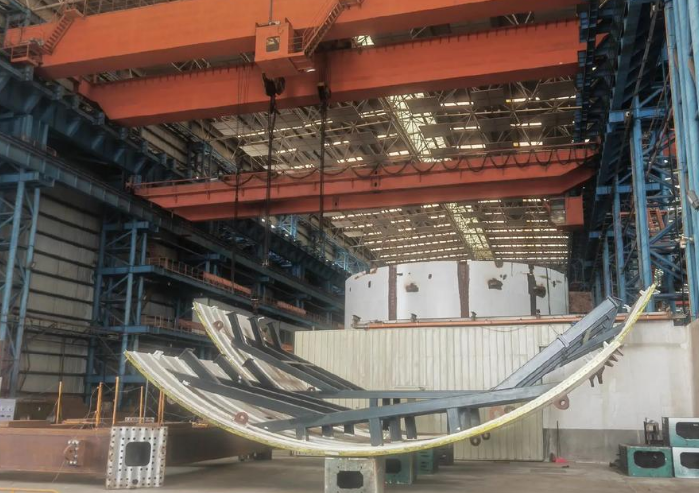

Main application fields![图片[2]-中国の高強度アルミ合金リベットと溶接加工:技術と強さで世界をリードする-大連富泓機械有限公司](https://jpdlfh.com/wp-content/uploads/2025/07/QQ20250706-201356.png)

Aerospace Aircraft Carcass Frame, Outer Wall Panels, Fuel Tank, Sheet Metal, and Engine Parts and Connections.

Railway transport: High-speed railway and underground railway body structure (sidewall, roof, bed), trolley parts, and interior parts.

New Energy Vehicle: Battery-packed Caisson, Motorised Caisson, Revolving Components, Lightweight Components.

High-end equipment: robot arms, precision machine mounts, special carriages, ship superstructures.

Key Considerations for Selecting a China Service Provider

Experiences with specific alloys and proxies: The success of using specific materials (e.g. 7075-T6 dissolved) in a project has been confirmed.

Technological Capabilities and Facilities: The Company has been able to demonstrate the sophistication and capabilities of its nuclear facilities (FSW, laser welding, etc.).

Quality Certification and Test Ability: Necessary and indispensable international quality system certification and full NDT ability are the basis and naturally.

Environments and SPS capabilities: Design for Manufacturing (DFM), Prospectus Simulation (PS) and Palladium (Palladium), and full Prospectus SPS capabilities.

Production scale and delivery time guarantee: Quantity requirements and emergency delivery capacity are evaluated.

Awareness of Intellectual Property Protection: Collaboration is safe and secure.

Judgement

China has built its reputation in the field of rebating and welding of high-strength alloys. We have excellent technology, excellent equipment, high quality, quick response, and excellent overall strength. Complex aerospace structures, high-efficiency and lightweight pursuit of new energy-generating automotive parts, China's manufacturers have selected materials to develop and mass-produced wanstrops and sorries, and the following customers are looking for ideal alternatives. Ideal patented alloy structural parts with high cost-effectiveness and reliability.

China's major high-strength alloys and machining services are now available for viewing! Expertise and experience in the use of Adebayers and Seeing Jumbo, China Smart Manufacturing supports the goal of lightweighting in a wide range of applications.

コア・キーワード China Aluminium Alloy Processing, High Strength Aluminium Alloy Rebate Joining, High Strength Aluminium Alloy Welding, Aluminium Mixing Friction Joining, Aluminium Reactive Joining, Aerospace Aluminium Alloy Processing, Aluminium Alloy Components for Railway Transport, New Energy Vehicle Lightweighting, Aluminium Structural Component Manufacturing, Precision Rebate Joining Sample, China's Manufacturing Ads Barntige, Aluminium Rebett Soldering Service, High Strength Aluminium Alloy Joining Technology

No comments