What is the future outlook of the Rebate/Solvent Manufacturing Industry in China?

Introduction

In today's changing world manufacturing industry, China's rebate and solvent joining manufacturing industry is an important part of the basic industry, and its development insights have attracted a lot of attention. This paper analyses the current situation, issues and future development trends of the rebate and solvent cement manufacturing industry in China, and provides valuable reference information for industry practitioners and related investors.

Analysis of Current Status of Rebate and Soldering Manufacturing Industry in China

Industry Size and Market Position

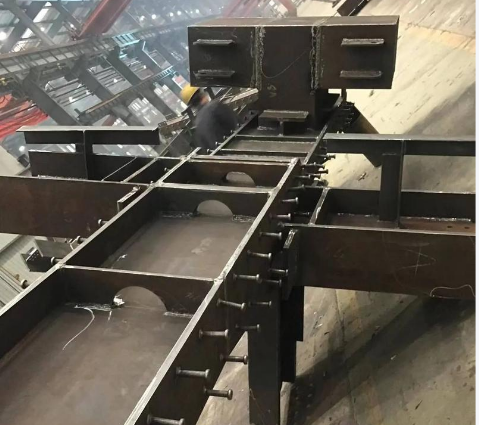

After decades of development, China's rebate manufacturing industry has become the largest producer and consumer of rebate products in the world. According to the statistics, the annual production of Rebettes and Solvents in China has exceeded 100 billion RMB, which is about 35% of the world market share. This huge industrial base is supported by China's manufacturing industry.![图片[1]-中国のリベット・溶接製造業の将来の展望は何か(変化する世界の製造業の現状、基礎産業の重要な一部としての中国のリベット・溶接製造業)-大連富泓機械有限公司](https://jpdlfh.com/wp-content/uploads/2025/06/QQ20250625-204231.png)

State-of-the-Art Technology

Currently, China's rebate/solvent manufacturing industry is showing the distribution of "Piramid-type" technologies:

On the photoshoot: The automated Interligent Soldering Technology is a big hand enterprise with a single grip of HON.

Chuo: Half of the companies are using semi-automated production equipment.

Next:A part of the SMEs are still working with the traditional handcrafts and are relied on for solving the problems.

Main application fields

Rebelt welding technology is widely used:

Construction (steel structures, bridges, etc.)

Automobile Manufacturing (Vodisolutions)

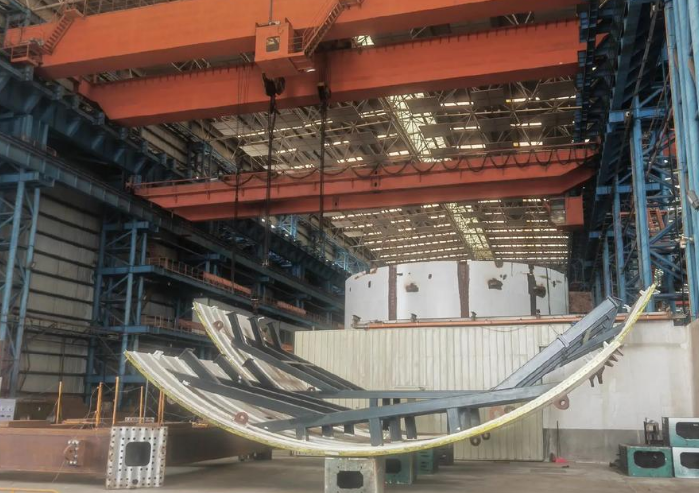

shipbuilding

Otto Kreb

aerospace

Metro

China's Rebate and Soldering Manufacturing Industry is Facing Up to the Challenge

Increase in cost of goods

China's population is declining, and the shortage of skilled workers is becoming a major factor in the development of the country's economy. Continuously rising labour costs are forcing companies to consolidate their profit margins, and the industry is moving to automation.

Intensification of International Competition

The Chinese rebate and solvent manufacturing industries are facing the competitive situation of "front and back attack" in the countries of Southeast Asia, where labour constraints are low and where the superiority of the hurdles market is being maintained, as well as in the advanced countries, where technological innovations are being adopted, by inducing foreign investments.

Environmental Conservation Consolidation

In addition, the environmental regulations and limitations on environmental protection are being faced directly by the environmental pollution of gas, slag, and environmental fugitive noise from the dissolution project, and the environmental protection investment of enterprises has been increased.![图片[2]-中国のリベット・溶接製造業の将来の展望は何か(変化する世界の製造業の現状、基礎産業の重要な一部としての中国のリベット・溶接製造業)-大連富泓機械有限公司](https://jpdlfh.com/wp-content/uploads/2025/06/QQ20250625-204151-800x406.png)

Changes in Raw Material Prices

Uncertainty in the prices of steel and other raw materials has a direct impact on the level of production and profitability of rebel and bonding companies.

Development Trends of Rebate and Soldering Manufacturing Industry in China

Automation and Intelligent Transformation

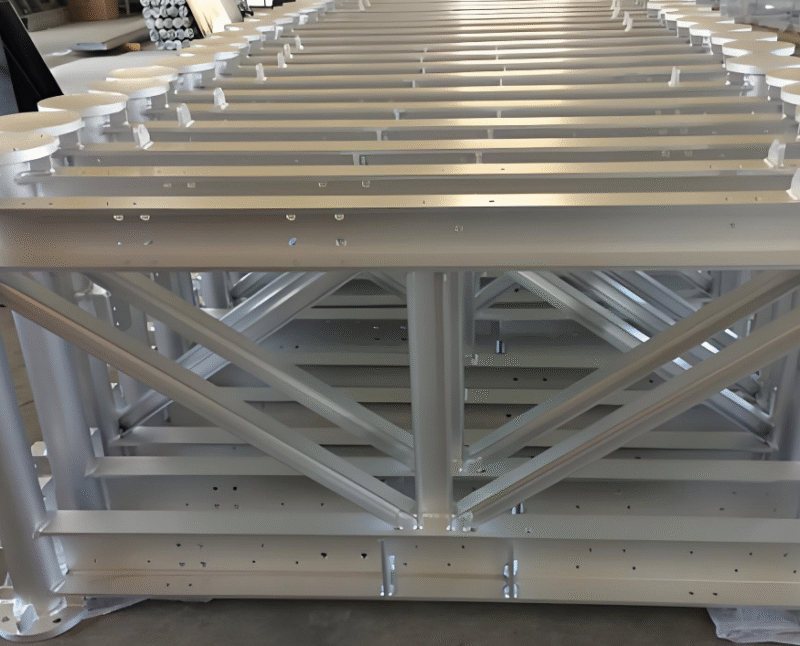

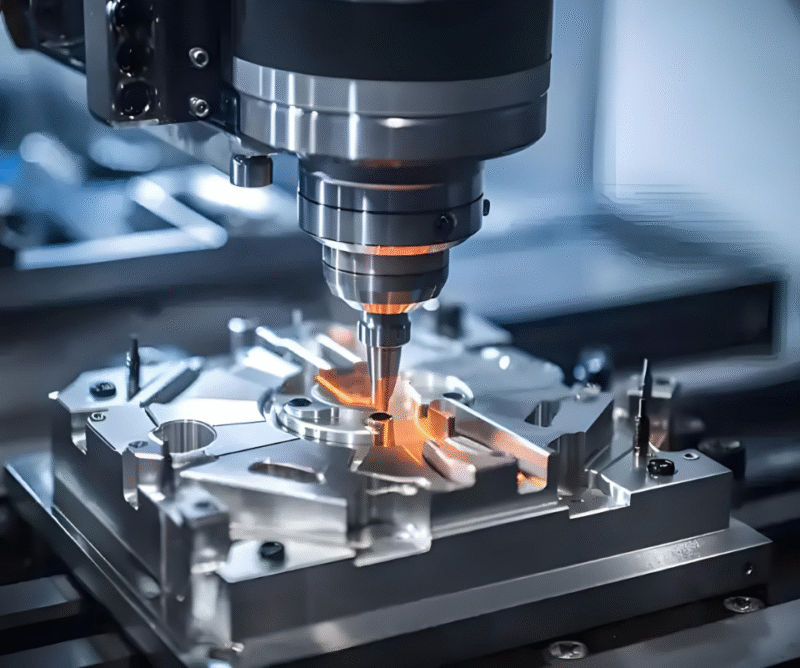

In the next 5 to 10 years, China's Rebate and Soldering Manufacturing Industry will be accelerated by the development of automation and Intelligence:

The popularity of solvent-bonded revolver is greatly improved

Integration System for Automatic Optimisation of Proximity Parameters.

Dissolving Prospectus Simulation and Modelling Technology with Digital Twin Technology

Application of New Material and New Prospectus

On the emergence of new materials, Rebate technology is facing new opportunities and issues:

Research and Development of Welding Prospectus for High Strength Steels and Aluminium Alloys as Light-Weight Materials

The advancement and application of laser bonding, friction mixing bonding, and other new products.

Brexit in Heterogeneous Material Joining Technology

Greene Manifesto and Continuous Possible Development

The environmental component is a key factor in the transformation of the industry:

Development of Low-Hike and Low-Energy Solvable Properties

Soldering Sklap Reservoir Technology

Clarifying Energy in Solution Manufacturing

Service-based Manufacturing Models

The service-based manufacturing industry from the production-based manufacturing industry in the past:

Single-unit products are supplied with solids.

Remote Monitoring and Foreknowledge Preservation Services

Barry Mignon and Applications of Soldering Data

Policy Support and Market Opportunities

National Policy Guidelines

The "メイド・イン・チャイナ 2025" strategy is a major direction of attack on the Intelligent Manufacturing Industry, with industrial transformation and a revitalised APC, and policy support:

Intellectual Property Rights and Manicrafts Special Funding Assistance

Tax incentives for technological innovation

Habitat Enterprise Recognition

Market opportunities arising from the "One Belt, One Road" idea

The Infrared Connection is born out of a huge market need:

Overseas Projects with Higher Solving Needs

Opportunities for Export of Welding Machines and Technologies to China

New Spaces for International Capacity Collaboration

Application Extension in New Field

New technologies such as new energy, electric vehicles, ocean engineering, and new applied systems are emerging:

Pawabatelli Soldering Technology

Welding of Steel for Offshore Wind Power Generation

Solubilisation of hydrological energy storage tanks

Conclusion and Remarks

Advice for the future

In summary, China's rebate/solution manufacturing industry has a broader outlook for future development, and there are a number of issues that need to be addressed by 2030.

The industry has been able to complete the migration to automation, and Integral has seen a significant upward shift in its revenues.

International Competitiveness of Large-Scale Enterprises is Strengthened.

Market centres for medium and high price bands may be extended.

Green Manufacturing as an Industry Standard

Corporate Development Proposal

Investment Extension for Research and Development: Research and Development of Automation Equipment and New Soldering Plants

Complex Labour Development: Solving Skills and Digital Technology in Preparing Workforce

Extension of Service, Barrier and Chain: Stylish Processing to Total Solution and Probander Switching

Overseas Markets: Catching the "One Belt, One Road" Challenge and Realising International Development

China's Rebate and Soldering Manufacturing Industry is in an important period of transformation and Apex Grading, and those who grasp the technological trends and actively respond to corporate issues will be able to take advantage of the favourable market competition in the future, and work together to push forward China's Soldering "Soldering Force". Moving Forward on "Solutility".

No comments