The design and manufacture of passthrough devices is the core of the industry. The optimisation of smoothing, manicuring, service, trauma, and surcharging will help to reconstruct the industry and to explore new opportunities for growth in the business sector.

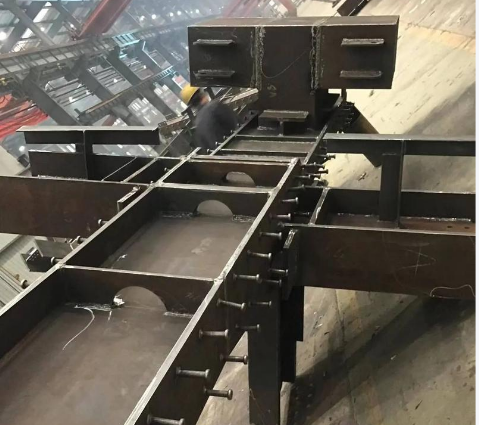

This article: Industry is the backbone of modern economy, and the equipment manufacturing industry is the backbone of the "machine-machine" industry. It is an important part of the industrialisation of the country, and an important part of the overall national strength, as it is responsible for the production of the necessary sub-areas of machinery operation, major technical equipment, and automated production laboratories.![图片[1]-設備製造業:国の最も重要なツール、インテリジェント製造を通じて将来の市場を獲得する方法-大連富泓機械有限公司](https://jpdlfh.com/wp-content/uploads/2025/11/QQ20251002-201911.png)

1. Understanding the Scope and Importance of the Equipment Manufacturing Industry The equipment manufacturing industry is a wide-ranging industry that includes the following: power equipment: gas turbines, hydraulic turbines, and atomic power generation equipment. CNC machine tools: the "tooth" of modern manufacturing, for precision machining. Engineering machinery: Cutting machines, clowns, and steel mills. Agricultural machinery, fibre optic machinery, printing machinery, and other special machinery. We provide powerful technical means and material basis for national economy and national defence construction.

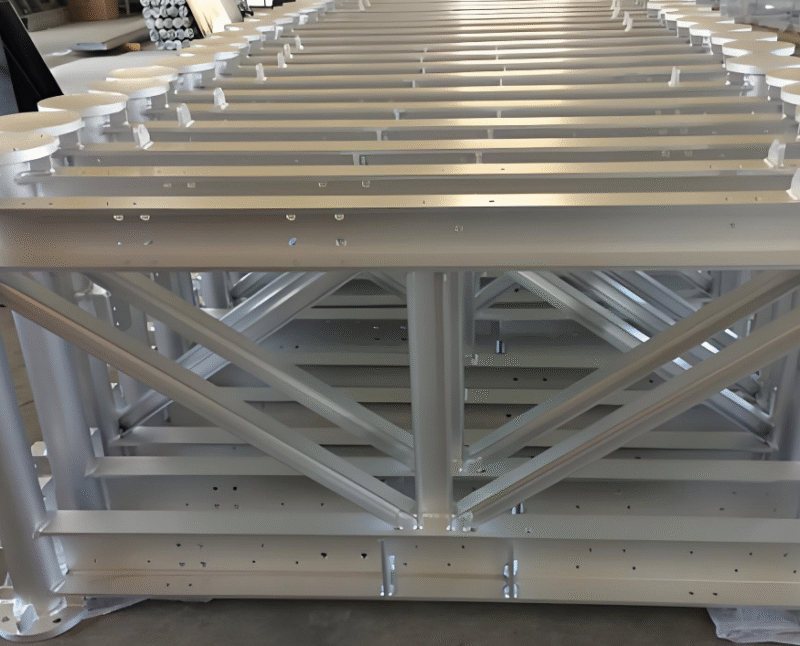

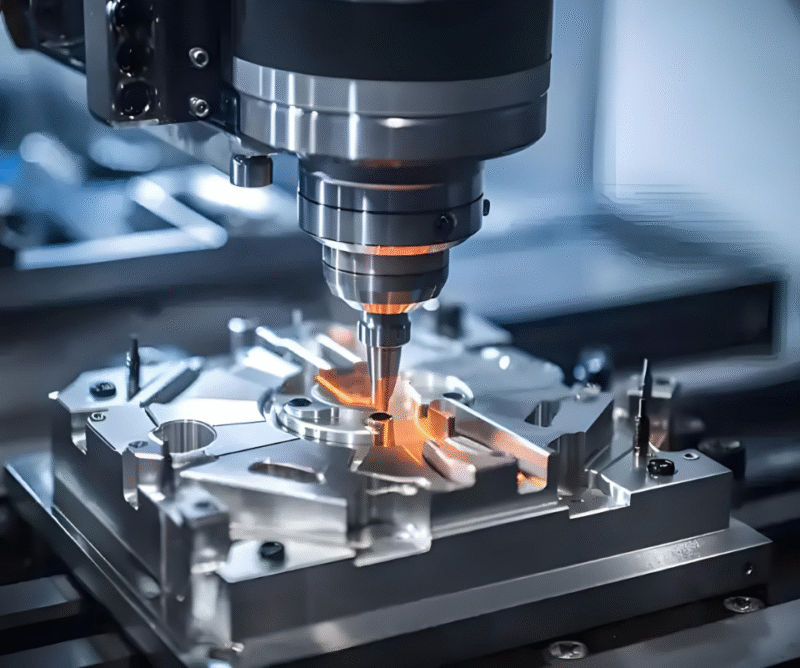

2. Intelligent manufacturing is the core of the driving force Under the wave of Indastry 4.0, the equipment manufacturing industry is now in the process of developing its own intelligent airplanes. Soft manufacturing system: Smaller, more varied, and more responsive to market needs, with production labels that can be quickly adjusted to suit the needs of the market. Application of Arditeb and Manifold Chaining: 3D Printer technology is used to make complex parts of prototype, and the final product is made directly, and the development service is shortened dramatically. Optimisation based on data: The customer-side equipment operation data is used to optimise the design and performance of next-generation products.![图片[2]-設備製造業:国の最も重要なツール、インテリジェント製造を通じて将来の市場を獲得する方法-大連富泓機械有限公司](https://jpdlfh.com/wp-content/uploads/2025/11/QQ20251002-202304.png)

3. "モノ売り」から「コト売り」への転換 大手機器メーカーはもはや機器を単発で販売するだけでなく、ライフサイクル全際にわたるサービスの提供へとシフトしている。 Remote Operation and Maintenance Services: With the Intelligent Network and Plateform of Mono, we provide 24 hours 365 days monitoring of machine status and remote diagnostics to our customers. Full-range and private companies: to make the initial investment of the customer, and to combine the interests of both the company and the customer.

4. Strengthening the Resilience of the Spline Chain The stability of the Spline Chain is extremely important in the long run of the machine manufacturing industry. In order to deal with potential geopolitical problems and unpredictable situations, the mainstream strategy is to use green bars, reiators, and regional barcades. Offer: The equipment manufacturing industry is on the path of change through technological innovation and business model innovation. By actively engaging in smart and manicure technology, deepening service transformation, and building a comprehensive service platform, companies will become the "most important weapon of the nation".

No comments