In-depth knowledge of modern timesMetallurgical EquipmentThis is a major technical blueprint for upgrading the efficiency, quality, and environmental performance of metal fabrication, such as electric arc furnaces, continuous lathes, automatic control systems, and so on.

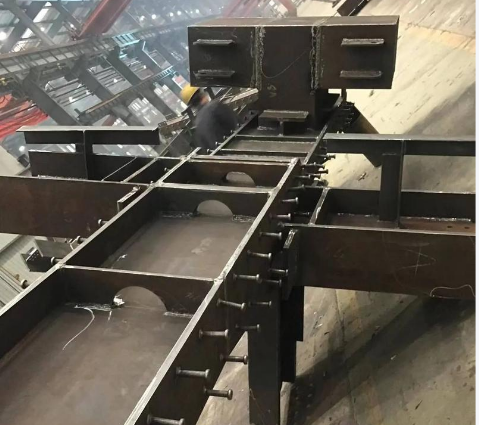

This:The progress of metallurgical industry is greatly dependent on the innovation of the core metallurgical machine. In order to achieve high purity of metal materials from paraffinum liquidum, it is necessary to support high reliability machine with high efficiency and reliability in the process of washing and cleaning. We would like to introduce the current state-of-the-art in metallurgical machine technology to you.![图片[1]-冶金设备技术前沿:从高效熔炼到智能化控制的全面革新-大连富泓机械有限公司](https://cndlfh.com/wp-content/uploads/2025/11/QQ20251002-201616.png)

1.High efficiency dissolution equipment: the core of the metallurgical programme Dissolution is the core of metallurgy, and the performance of its equipment directly determines production efficiency and energy consumption. Ultra High Output Electro-Air Furnace: In modern iron and steel production, the importance of the Electro-Air Furnace has increased due to its flexibility and environmental advantages. The new generation of ultra-high output EAFs has significantly shortened the manufacturing process, reduced unit power consumption, and reduced the amount of nuclear equipment for short-term steel production. Flushing Furnace: In the manufacture of non-iron metals (copper, nickel, etc.), the flushing furnace represents the development direction of green manufacturing with high strength, low energy consumption, high sulphur recovery and other advantages.

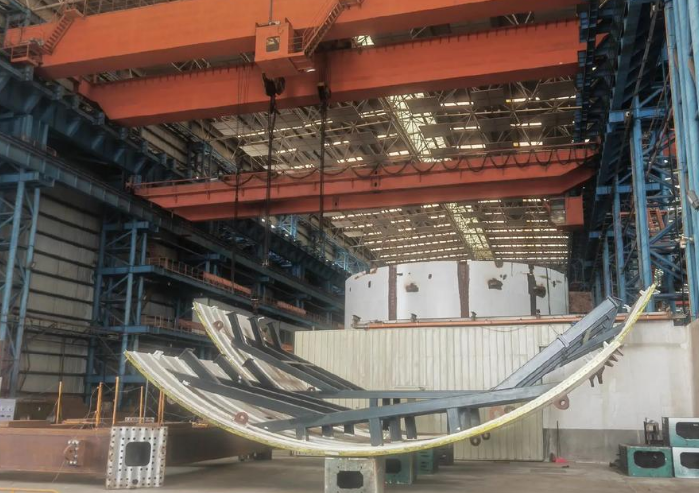

2. Continuous Casting Equipment: Quality and upward adjustment of the creep rate Continuous Casting Equipment is a basic process that replaces the gold-type casting process with the direct solidification of steel to the desired shape of the VRT. Thin Slab Continuous Sequencing and Consolidation Technology: Continuous Sequencing and Consolidation Technology is the key to achieve high efficiency and low-cost production through the connection of a seamless process to a seamless process, which can significantly reduce energy consumption, shorten the production process, and achieve high efficiency and low-cost production. Intelligent mould: The mould is the "heart" of the continuous manufacturing machine, and the internal material and advanced control system monitor the liquid level and cooling strength of the steel, so that the internal quality of the vibrating mould is uniform and stable.![图片[2]-冶金设备技术前沿:从高效熔炼到智能化控制的全面革新-大连富泓机械有限公司](https://cndlfh.com/wp-content/uploads/2025/11/QQ20251002-201517.png)

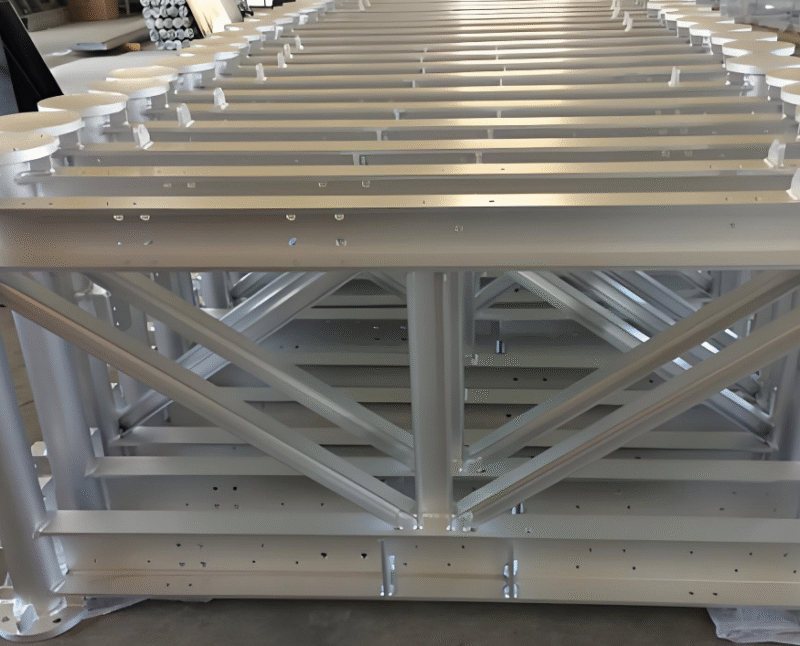

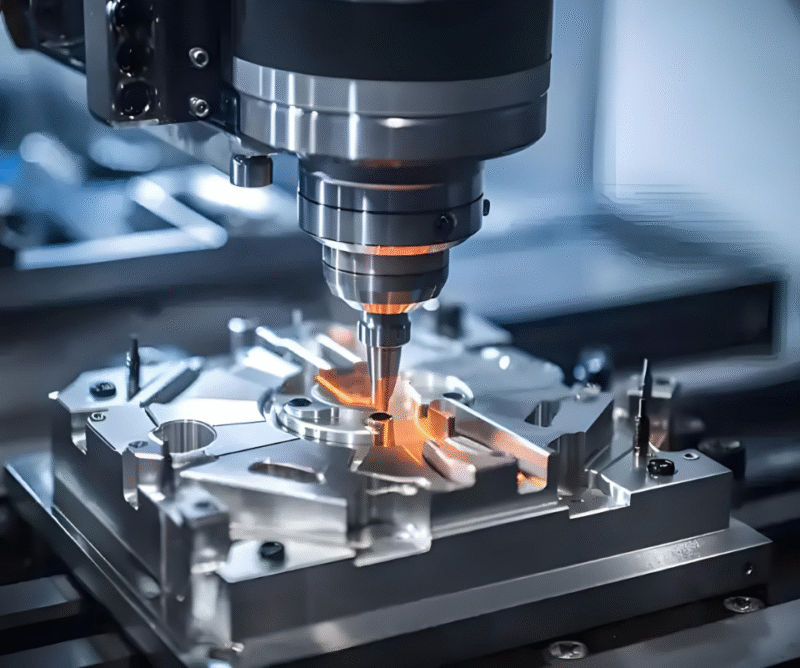

3. Automation and Intelligent Control System Modern metallurgical plants are developed in the direction of "Blanket Plant", which is backed by a powerful control system. Prospect control system: Thousands of parameter such as temperature, pressure, composition, etc. are obtained from the Realtime system to optimally control and preserve the production process in the best possible condition. Pre-knowledgeable preservation system: machine vibration, temperature and other data analysis, early warning of potential faults, regular maintenance, and avoidance of unplanned damages. 4. Environmental Protection and Resource Facilities Environmental protection is under pressure, and the rapid development of related facilities is advancing: flue gas desulphurisation and de-choking facilities: Sulphur compounds and choking agents in the exhaust gas are efficiently removed. Metallurgical Slag Treatment and Resource Utilisation Equipment: Solid wastes from blast furnace slag and steel slag are treated as raw materials for construction materials, and the wastes are transformed into treasure.

Overview:ヒュンダイMetallurgical EquipmentLarge-scale, high-efficiency, Intelligent, and Greening are the directions for rapid development. Investment in advanced metallurgical equipments is the key to enhance the competitiveness of enterprises, which is the basic guarantee for the sustainable development of metallurgical industry.

No comments