Mechanical workshop based on reliability of customersWhat are the details of the injection moulding service? We provide a complete evaluation system of equipment capacity, quality systems, technical commissions, and case studies to ensure the long-term stability of our strategic services.

In cases where the core of your company's products are precision parts and where long-term, stable, high-volume production and external machining is necessary, a purely "Plattform Comparison" with first-class mechanical machining and external machining service providers and deep mutual trust in your company's paternoster system is a strategic necessity and a necessity for your company. This note provides a series of professional evaluation forums for Anata's most reputable manufacturing partners.

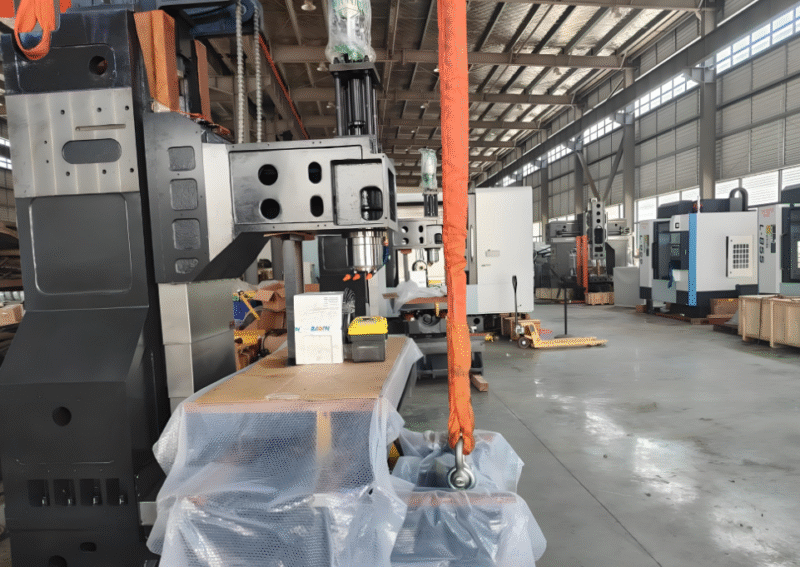

A. Prices: High-quality machining of the four coats of the machine tool system, the Bargaining Factory, and the parts and components of the machine tool factory. Quality Assurance: The systematic quality system eliminates the risk of the development of scrips. Technical support: We can optimise the design and reduce the costs by manufacturing possible design adobes, so as to achieve high efficiency. Highly reliable products: Stable production capacity and production capacity, and the tracking of the project. Risk Avoidance: Standardised management avoids potential risks such as data leakage and intellectual property disputes.![图片[1]-機械加工アウトソーシング・パートナーの選び方:2025究極の評価ハンドブック-大連富泓機械有限公司](https://jpdlfh.com/wp-content/uploads/2025/11/QQ20251102-193830-800x489.png)

Secondly, the evaluation of the external machining in the professional machining workshop チェックリスト The following points should be confirmed during the on-site inspection and contact: 1. Hardware: equipment and machining capacity Equipment List: CNC machine (3-axis, 4-axis, 5-axis), rotary disc, flange disc, jogging disc, 3-axis, and so on, which are suitable for the products of your company? CNC machine (3-axis, 4-axis, 5-axis?) suitable for Gosha's products. Hairpin, rotary discs, slide discs, sloughs, three-dimensional measuring machines, and so on. What are the newest equipment and brands? Processing area: Spinning, flute, grinding, heat treatment, surface treatment, and all other processes from the machining process plan. (Maximum machining capacity: What is the maximum size, weight, and accuracy of parts that can be processed? 2.ソフト力:Quality and Management System Quality Certification:ISO9001などの国際な質質質システム認證を取得しているか。 Inspection capability: Advanced inspection equipment (CMM, laser scanner, etc.) and specialised QC chambers are available. Production Management: We use MES (Manufacturing Execution System) for production skids and material management. Documentation: We provide complete FAI (One Time Inspection Report), material certificates, and other quality documents.

第三に、コミュニケーションから協力へ:機機工場をスクリーニングするための重要なステッップ Initial コミュニケーション:あなたの部件の図面を提供し, the speed of response of a technician and the depth of understanding of the problem is observed on the counter side. This reflects the extent of the direct programming system. Solution Requests: Provision of engineering plans and inputs from the relevant parties. The project manager will explain in detail the processing strategy of the company. Requirements for the Causeway: We will confirm the past performance of our company and the products we processed in the same way. On-site inspection (in the case of a note from Oguchi): We will check the production environment, the condition of equipment, and the management framework. Initial trial: This is the most important port of call. Through the trial of the small rote, quality, lead time, and communication efficiency are very much on the table.

On the fourth day of the month, Digital and Concrete: Traditional Machining Workshops and the Application of Automotive Processing Today, the mechanical machining workshops in Topscotch are being actively utilised for digitalisation. We are actively using the mainstream Ampli in the machining centre to manage the attention and communication with customers. (Note: The Link to Note 2 is a separate Customer Portal that is used by the Realtime Team to view the progress of production drill. This is a demonstration of the modernisation of the customer account and the improvement of internal management efficiency through the modernisation of the camera.

Conclusion The selection of a machine tool for processing Patona is an important strategic decision. In order to make this decision, it is necessary to evaluate the strengths, systems, and corporate culture of the company in a comprehensive and critical manner. Ideal patents are those that are highly reliable, and have a strong solid foundation in service providers. The ultimate success of the product is to invest the necessary time and labour.

No comments